Difference between revisions of "Tagger Microscope Mechanical Design"

Senderovich (talk | contribs) |

Senderovich (talk | contribs) m |

||

| Line 18: | Line 18: | ||

[[Image:LinEng_4118-01_StepMotor.jpg|thumb|117px|Lin Engineering 4118L-01 Stepping Motor (1.9" variety)]] | [[Image:LinEng_4118-01_StepMotor.jpg|thumb|117px|Lin Engineering 4118L-01 Stepping Motor (1.9" variety)]] | ||

| − | + | [[Image:MotorSupport closeup.png|thumb|109px|Support of fiber module railing directly on the threaded motor shaft.]] | |

| − | [[Image:MotorSupport closeup.png|thumb| | ||

| − | |||

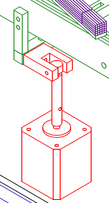

The simplest design for a 3-point adjustable plane on which the fiber modules would be mounted is to have it rest directly on motor shafts positioned vertically. The threaded shafts can lift and lower their respective points by mating them to a threaded through-holes on an elbow assembly that will keep that point fixed but flexible with respect to motion at other points of adjustment. The adjacent drawing shows how the shaft actually couples to the railing via two axles (the cylinder mating to the shaft and screw connecting the block to the rail structure) to allow for the motion at other points of adjustment. | The simplest design for a 3-point adjustable plane on which the fiber modules would be mounted is to have it rest directly on motor shafts positioned vertically. The threaded shafts can lift and lower their respective points by mating them to a threaded through-holes on an elbow assembly that will keep that point fixed but flexible with respect to motion at other points of adjustment. The adjacent drawing shows how the shaft actually couples to the railing via two axles (the cylinder mating to the shaft and screw connecting the block to the rail structure) to allow for the motion at other points of adjustment. | ||

| Line 33: | Line 31: | ||

== Adjustment to the Electron Crossing Angle == | == Adjustment to the Electron Crossing Angle == | ||

| − | [[Image:ParallelRailingConcept.png | + | {| |

| − | [[Image:FiberModuleMounting.png | + | | [[Image:ParallelRailingConcept.png|370px]] |

| + | || [[Image:FiberModuleMounting.png]] | ||

| + | |} | ||

A simple dynamic parallel railing system was devised to allow flexibility for the electron crossing angle. In the range of useful photon energies (3-12 GeV) the crossing angle (measured from the focal plane) is calculated to change from 8 to 60 degrees. The adjacent figure illustrates a set of "rails" kept apart by beams parallel to electron trajectory. As shown, this allows for properly positioned mounting sites for both ends of the fiber modules. Additionally, in the high energy photon range (where electrons have low energy and bend significantly) the errors accumulating from keeping the fibers parallel are no longer insignificant. The right-hand side of the parallelogram shown is actually equipped with a slot to allow the lower rail to rotate inward and deviating from this parallel arrangement. It can be shown that the natural alignment of the fiber modules contains allows a small angular shift from one fiber module to the next, satisfying to the necessary extent the alignment with the electron trajectories. | A simple dynamic parallel railing system was devised to allow flexibility for the electron crossing angle. In the range of useful photon energies (3-12 GeV) the crossing angle (measured from the focal plane) is calculated to change from 8 to 60 degrees. The adjacent figure illustrates a set of "rails" kept apart by beams parallel to electron trajectory. As shown, this allows for properly positioned mounting sites for both ends of the fiber modules. Additionally, in the high energy photon range (where electrons have low energy and bend significantly) the errors accumulating from keeping the fibers parallel are no longer insignificant. The right-hand side of the parallelogram shown is actually equipped with a slot to allow the lower rail to rotate inward and deviating from this parallel arrangement. It can be shown that the natural alignment of the fiber modules contains allows a small angular shift from one fiber module to the next, satisfying to the necessary extent the alignment with the electron trajectories. | ||

| − | Angles as low as 8 degrees require ~60" rails to fit all 100 channels. Rails made out of aluminum (chosen for the ease of machining and to keep the load on the adjustable supports light) will sag significantly compared to the thickness of the fiber, | + | Each rail mentioned above consists of two rigid metal strip spaced to allow a standard 4-40 bolt between them. Each module sinks two long 4-40 bolts (3" apart on the module) into the slot of the two corresponding rails. They may be tightened against the rail from below, if desired. Thus the geometry of the rails specifies the alignment of the fiber modules. |

| + | |||

| + | Angles as low as 8 degrees require ~60" rails to fit all 100 channels. Rails made out of aluminum (chosen for the ease of machining and to keep the load on the adjustable supports light) will sag significantly compared to the thickness of the fiber, if they are supported on the edges. Optimized positions have been found (roughly 28% of the way from the edge) to minimize the sag. Also, thickening the rail in the direction perpendicular to the ground to the maximum reasonable degree helps significantly (the sag is inverse to the third power of this dimension). Using these methods, the calculated sag has been reduced to about 35 μm | ||

| + | |||

| − | == | + | == CAD Drawings == |

CAD Models | CAD Models | ||

Revision as of 00:59, 27 August 2008

Page under construction.

A light-sealed enclosure for the Tagger Microscope is under design. The following requirements have been set forth to constrain it:

- hermetically sealed from light

- if possible, have the ability to work at all usable energies (not just ~9 GeV of GlueX)

- motorized, internal, 3-point adjustment to bring the fiber array plane to appropriate alignment with that of the electrons

- plan for SiPM bias and amplifier board alignment to fiber waveguides (out of the electron plane)

- appropriate room for bending these stiff 2 mm square fibers

- pulser assembly for testing the Tagger without beam

- clearance from all structural elements in front of the scintillators to avoid multiple scattering and bremsstrahlung as well as minimal material downstream of the scintillators

Solutions to these is discussed below.

3-point Fiber Array Adjustment

The simplest design for a 3-point adjustable plane on which the fiber modules would be mounted is to have it rest directly on motor shafts positioned vertically. The threaded shafts can lift and lower their respective points by mating them to a threaded through-holes on an elbow assembly that will keep that point fixed but flexible with respect to motion at other points of adjustment. The adjacent drawing shows how the shaft actually couples to the railing via two axles (the cylinder mating to the shaft and screw connecting the block to the rail structure) to allow for the motion at other points of adjustment.

In this arrangement friction on the thread due to weight of the load is the principle constrain on the choice of motor torque. A conservative approach to this choice would be to allow up to 5 lb of weight per support point, dry-sliding coefficient of friction between pieces of aluminum of 1.4, about 1/8" lever arm of the torque shaft. Torque capability an order of magnitude above that required to overcome the situation of these parameters (14 oz⋅in)

The 83 oz⋅in Lin Engineering 4118L-01 (1.9") Step Motor has been chosen. The unit is close in price to the lower torque models and does not exceed the 2 A limit of the inexpensive driver (meant for lower-end motors).

The combination of these devices have been found easy to control: the driver has simple direction and step resolution selection pins and uses TTL pulses as step commands. The shaft of the motor, which comes smooth (as in the adjacent picture) when bought from distributors. However, it tested to be more than soft enough to machine a flat into it. A cylindrical "sleeve" with threaded outer surface may be inserted over it and tightened against the flat a small headless screw.

Adjustment to the Electron Crossing Angle

|

|

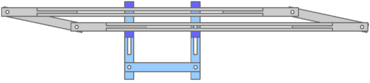

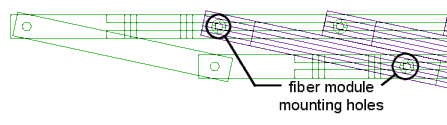

A simple dynamic parallel railing system was devised to allow flexibility for the electron crossing angle. In the range of useful photon energies (3-12 GeV) the crossing angle (measured from the focal plane) is calculated to change from 8 to 60 degrees. The adjacent figure illustrates a set of "rails" kept apart by beams parallel to electron trajectory. As shown, this allows for properly positioned mounting sites for both ends of the fiber modules. Additionally, in the high energy photon range (where electrons have low energy and bend significantly) the errors accumulating from keeping the fibers parallel are no longer insignificant. The right-hand side of the parallelogram shown is actually equipped with a slot to allow the lower rail to rotate inward and deviating from this parallel arrangement. It can be shown that the natural alignment of the fiber modules contains allows a small angular shift from one fiber module to the next, satisfying to the necessary extent the alignment with the electron trajectories.

Each rail mentioned above consists of two rigid metal strip spaced to allow a standard 4-40 bolt between them. Each module sinks two long 4-40 bolts (3" apart on the module) into the slot of the two corresponding rails. They may be tightened against the rail from below, if desired. Thus the geometry of the rails specifies the alignment of the fiber modules.

Angles as low as 8 degrees require ~60" rails to fit all 100 channels. Rails made out of aluminum (chosen for the ease of machining and to keep the load on the adjustable supports light) will sag significantly compared to the thickness of the fiber, if they are supported on the edges. Optimized positions have been found (roughly 28% of the way from the edge) to minimize the sag. Also, thickening the rail in the direction perpendicular to the ground to the maximum reasonable degree helps significantly (the sag is inverse to the third power of this dimension). Using these methods, the calculated sag has been reduced to about 35 μm

CAD Drawings

CAD Models

3D views of the assembled Tagger

- Front View

- Side, perspective view from under beam plane

- Fiber module and railing close-up

- Railing support and adjustment motor structure

- View of "chimney" array for holding fiber waveguides against the photo-sensor/pre-amp PCB

Dimensioned Drawings