Heated Alcohol Tests

Jump to navigation

Jump to search

When the light guides were placed in heated ethanol concentrations, damage occurred to the fibers' cladding. Because it was significant damage, many concentrations were tested.

The procedure for the heated alcohol tests can be found here.

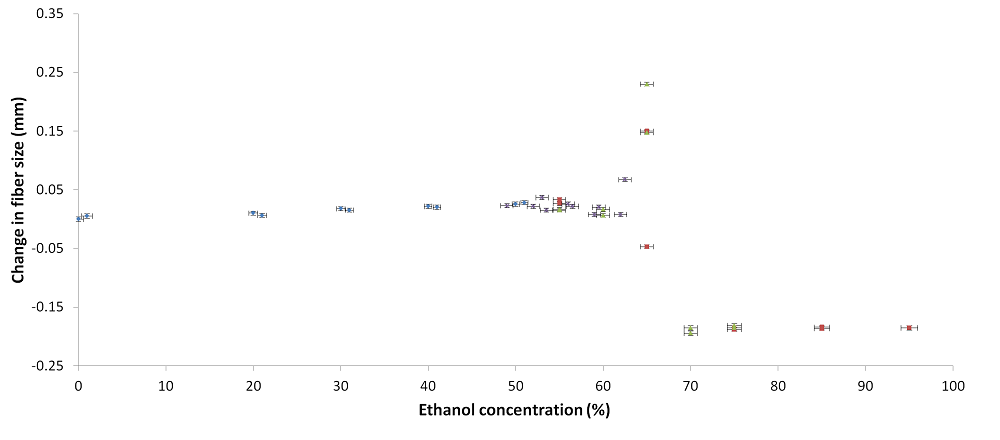

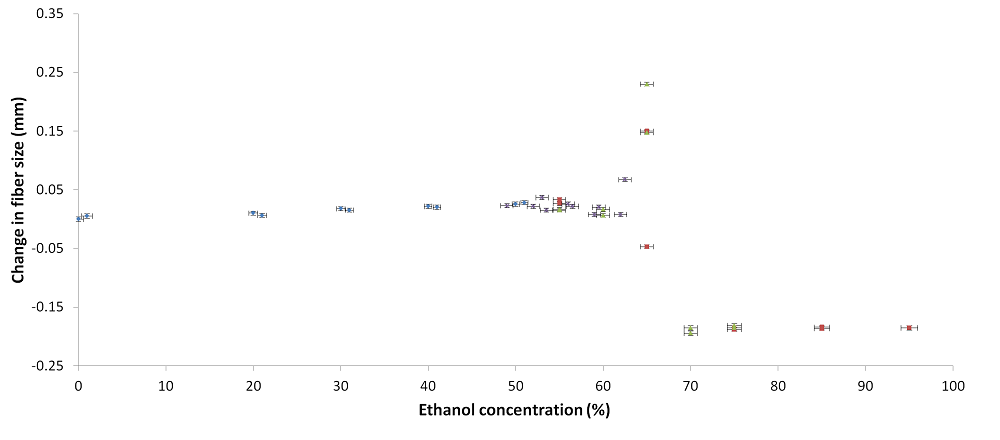

Above is the plot of all of the data collected from the heated alcohol tests. The different colors represent the individual tests. It appears that the fibers swell slightly in size until around 65%, where their widths greatly increase. However, after the 65% mark, the fibers have a negative change in width which it is when it is believed that the entire cladding is removed. This information is very important when considering what temperature and concentrations of ethanol can be used to clean the fibers.

Here you can see how the ethanol concentrations become increasingly cloudy as the ethanol concentration increases. The vials' concentrations are as follows: 55%, 55%, 60%, 60%, 65%, 65%, 70%, 70%, 75%, 75%. We believe that the vials get cloudier because of the increasing damage to the fibers cladding.