Hardware for Mounting of Diamond Radiators

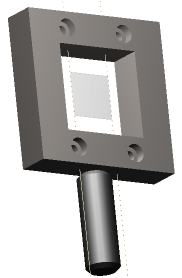

Mounting Bracket

The following hardware was built in preparation for the May, 2009 CHESS run.

The intended wire for clamping in this bracket is the 20 μm diameter tungsten wire borrowed from CMU. The bracket should have the planarity to handle this. Assuming elastic deformation of the bracket around the wires, force of order 100 N is expected, yielding to a force of friction well above the above the elastic limit of the wire (i.e. the wire will break before clamp releases it.)

Choice of Adhesives

Ellsworth Adhesives (Dist. Germantown, WI), Resinlab Cynergy Line:

- 6103 Metal Bonding Cyanoacrylate Adhesive [1]

- 6402 Toughened Cyanoacrylate Adhesive [2]

- Also available:

- AR 4305HP [5] (more general purpose, toluene-sensitive)

- 736 high temp. silicone sealant: 500F continuous use, degradation at 600F

Frank Murken Products (Dist. Schenectady, NY) (awaiting call)

Hernon Manufacturing, Inc. (Mfg. Sanford, FL) (in contact with Nicholas LaBarre)

- Supertacker 351 (easily dissolved with toluene etc.) [6]

- Silastomer 333

K.R. Anderson, Inc. (Dist.), Morgan Hill, CA

- Representative: nothing available

Master Bond, Inc. (Mfg.) (awaiting call)

Diamond Mounting Trials

Simple wire stretching exercises were performed. The wire is approximated to be well past its elastic limit bearing 50 g weight. A thumb screw threading two washers going into a threaded stand-off (long nut) provided a nice 4.8 g weight that can clamp wire. So, a wire loop is created by clamping the ends of a wire segment between the washers by tightening the thumb screw.

The tungsten wire was stretched using this weight and the shanks of cap head screws to keep the segments parallel. Playing with the first setup showed that the wire breaks quite easily and indeed, breaks before there is enough force to release it from the clamp of the bracket. The experience also showed that the wire is easily denatured (observed through kinks present even when stretched) so care must be taken in taking it off the spool and navigating around the supports.

All following gluing tests were performed with the Supertacker 351 mentioned above. This adhesive turned out to be a bit too viscous for depositing on such thin wire. It did, however, match our other criteria very well. The trick for using it with these wires was to get inside tweezers and slide them gently with the wire in the opening of the tweezers. A somewhat sloppy layer is deposited on the wire that should still be quite tacky during the minute or so while a sample is deposited. In fact, it grips quite well upon first contact with a clean surface, such that alignment of the sample's edge with the wire is difficult.

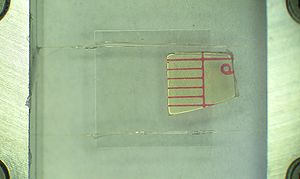

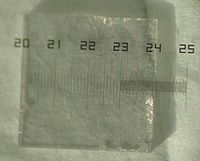

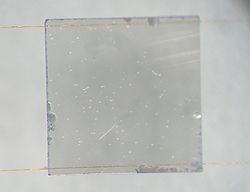

Figure 3 shows a square piece of glass, 12 μmm on the side, glued to the wire for practice. A much smaller diamond from BNL, currently 300 mm thick is shown in Figure 4. The shank of a 6-32 screw was thought to be a good spacer (Figure 5) for the wires but its roughly 3.5 mm diameter would take up a bit too large a margin of the diamond. The minor diameter of a 10-32 screw at about 3.7 mm seemed more appropriate. The wires were stretched with the latter prescription and the diamond was glued (Figure 6).

Minimal Supply List for Diamond Mounting

The following is a useful minimal tool kit for mounting the diamonds on wires clamped in the holder described above.

- Supertacker 351

- toluene

- alcohol

- kim wipes

- cotton swab tips

- clear plastic wrap

- foil

- Scotch tape

- scissors

- hex driver for size 4 cap screw

- tweezers (point tip preferred)

- (2) 10-32 screws

- ~5g weight with wire clamp (thumb screw, mating threaded stand-off, 2 washers)

- twist ties

- recommended: vice, 2" mouth minimum