BW June 2015

6/9: I ran one of my new versions of the LabVIEW program, but no prompt appeared for saving a data file, and the netBooter outlet did not turn on. I closed the program and ran it again, but error 10001 appeared again, meaning that LabVIEW had lost contact with the DAQ. I opened Instacal and it said the DAQ was on the board list but was not detected, so I had to unplug the DAQ and reconnect it to the USB port. Instacal detected the DAQ and I calibrated it as "8 Single Ended." After that the LabVIEW program acquired data from the DAQ.

The air temperature in the box is not uniform, with each thermistor registering a different temperature. They are ranked in the following order by temperature, with the first being the coolest and the fourth the warmest:

1. Bottom Center

2. Front Left End

3. Middle Right End

4. Back Center

The USB connector for the DAQ is white and is plugged in next to the blue connector for one of the netBooters.

In Excel, to select all cells in a column before the next blank cell, press ctrl+shift+down arrow.

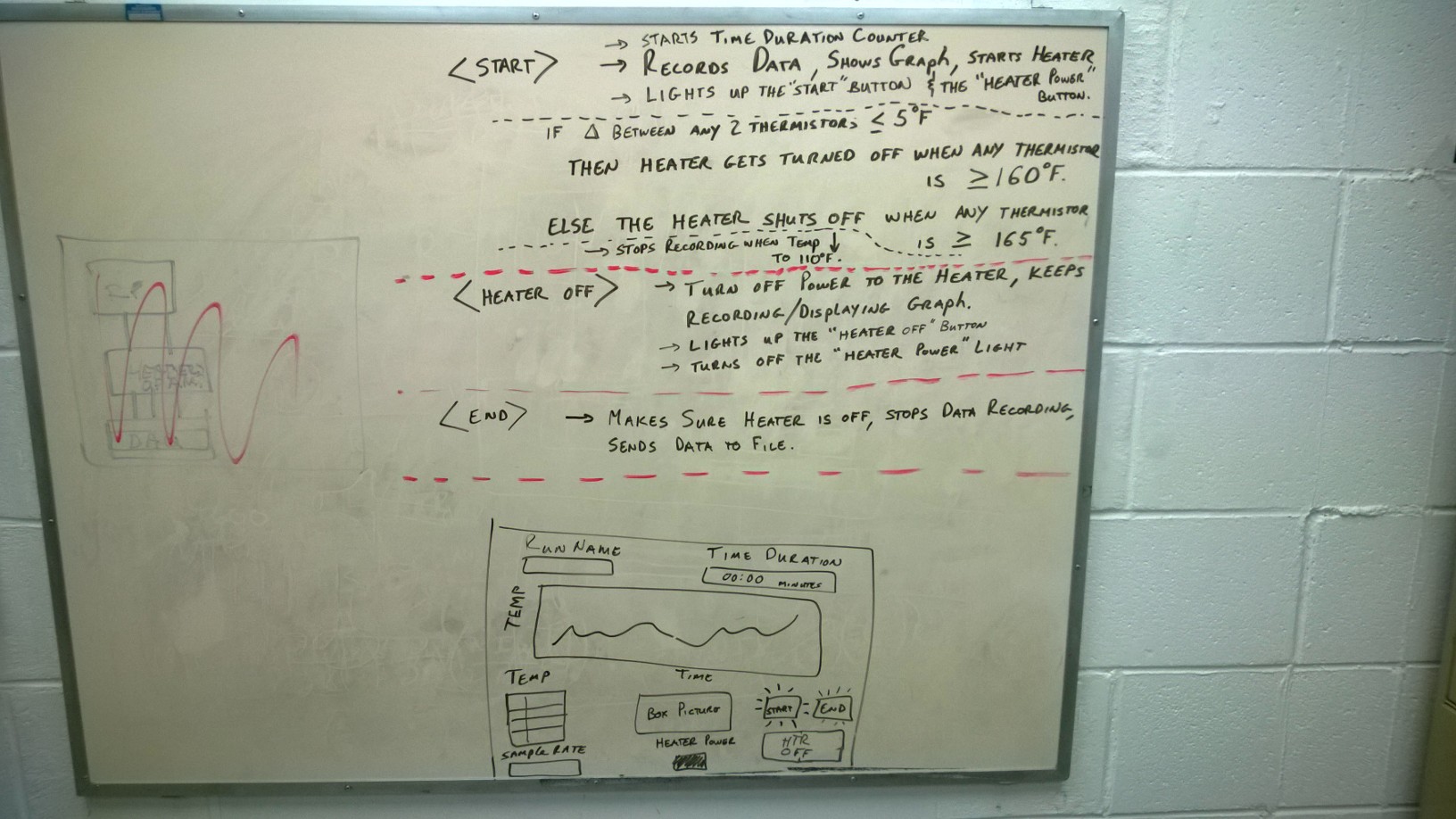

6/10-6/18: Following Jim's directions, I made improvements LabVIEW program. My top priority was to make it perform correctly, turning the heater on and off when necessary. I suspected that the program developed during the spring semester would heat the air in the box to 72 degrees C and turn the heater off as soon as it passed that temperature. However, when the air started to cool, it would drop below 72 degrees, and the program would turn the heater back on. Thus, the program was designed to keep the temperature close to 72 degrees for as long as it was running.

I tested the program by lowering the target temperature for heating to 35 degrees C and running it, and it performed just as I expected. Jim had told me that we needed the program to heat the air to 160 or 165 degrees F, then turn off the heater immediately and let the air cool to room temperature. I made changes to the program to make it let the air cool instead of keeping it hot, but I also added radio buttons to give the user optional control over the hot plate before the temperature reached the target. After the temperature reached the target, however, the program would turn off the heater and the user could not turn it back on.