Difference between revisions of "Analysis of Diamond Cantilever Vibration"

| Line 56: | Line 56: | ||

=== Methods === | === Methods === | ||

| + | [[File:Speaker_and_Cantilever.jpg|200px|thumb|right|the speaker and cantilever sharing a ring-stand]] | ||

*Step 1: Location of Resonance Frequencies | *Step 1: Location of Resonance Frequencies | ||

Analysis was run in order to find the exact locations of the resonance frequencies for each individual cantilever. The cantilevers were mounted horizontally one at a time using a clamp to hold them fixed from one end. A microphone was set up near the tip of the cantilever, at an approximate distance of three centimeters away. The cantilever was then given a short, non-periodic impulse (a flick near the end) and allowed to settle into its natural oscillatory frequencies undisturbed. The microphone picked up the compressed air waves made by the cantilever’s vibration. This process was repeated three times for each cantilever. From this data the resonance frequencies were extracted using Fourier analysis. | Analysis was run in order to find the exact locations of the resonance frequencies for each individual cantilever. The cantilevers were mounted horizontally one at a time using a clamp to hold them fixed from one end. A microphone was set up near the tip of the cantilever, at an approximate distance of three centimeters away. The cantilever was then given a short, non-periodic impulse (a flick near the end) and allowed to settle into its natural oscillatory frequencies undisturbed. The microphone picked up the compressed air waves made by the cantilever’s vibration. This process was repeated three times for each cantilever. From this data the resonance frequencies were extracted using Fourier analysis. | ||

| + | [[File:Laser_Spot.jpg|200px|thumb|right|A laser spot projected onto a screen for recording]] | ||

[[File:FourierFrequencies.pdf]] | [[File:FourierFrequencies.pdf]] | ||

| − | |||

*Step 2: Measuring Relative Amplitude: | *Step 2: Measuring Relative Amplitude: | ||

The optical lever technique was used to determine the relative amplitude of cantilever vibration at different points along the length. Each cantilever was mounted in the same fashion as before, and the clamp was attached to a ring stand. Also attached to the ring stand was another clamp holding a small speaker. Resonance was achieved by using the speaker to produce a constant sinusoidal output, which traveled through the ring stand to excite the cantilever. A class 111a laser pointer was mounted opposite the free end of the cantilever, pointing towards the fixed end. A white projection screen was mounted above the fixed end of the cantilever. In order to amplify the motion of the cantilever, which is normally very slight, the laser is reflected off the cantilever’s surface, and its own angle of motion is augmented by that of the cantilever relative to the horizontal at the point of reflection. | The optical lever technique was used to determine the relative amplitude of cantilever vibration at different points along the length. Each cantilever was mounted in the same fashion as before, and the clamp was attached to a ring stand. Also attached to the ring stand was another clamp holding a small speaker. Resonance was achieved by using the speaker to produce a constant sinusoidal output, which traveled through the ring stand to excite the cantilever. A class 111a laser pointer was mounted opposite the free end of the cantilever, pointing towards the fixed end. A white projection screen was mounted above the fixed end of the cantilever. In order to amplify the motion of the cantilever, which is normally very slight, the laser is reflected off the cantilever’s surface, and its own angle of motion is augmented by that of the cantilever relative to the horizontal at the point of reflection. | ||

| − | |||

To further increase this amplification, a system of mirrors was designed so that the laser would reflect off the cantilever multiple times over the same small lengthwise distance, multiplying the measured change in amplitude by the number of “bounces.” After coming out from the mirror system the laser projects onto the screen, where its sinusoidal motion reflects that of the cantilever. The motion of the laser point (keeping the number of bounces constant) was recorded at 1200 frames per second using a Casio Exilim Pro EX-F1 Digital Camera for each point along the length, moving at approximately one centimeter increments and recording the position of the center mirror relative to the cantilever base. | To further increase this amplification, a system of mirrors was designed so that the laser would reflect off the cantilever multiple times over the same small lengthwise distance, multiplying the measured change in amplitude by the number of “bounces.” After coming out from the mirror system the laser projects onto the screen, where its sinusoidal motion reflects that of the cantilever. The motion of the laser point (keeping the number of bounces constant) was recorded at 1200 frames per second using a Casio Exilim Pro EX-F1 Digital Camera for each point along the length, moving at approximately one centimeter increments and recording the position of the center mirror relative to the cantilever base. | ||

Revision as of 22:05, 21 January 2013

Purpose

In order to facilitate coherent bremsstrahlung radiation, the movement of the diamond radiator due to natural oscillation must be minimized. One possible way to mount the diamond involves supporting it from a single corner and leaving the other end free. The purpose of this work is to theoretically model the free vibrations of such a system to determine if it is a realistic solution to the problem of mounting the diamond.

Predictions

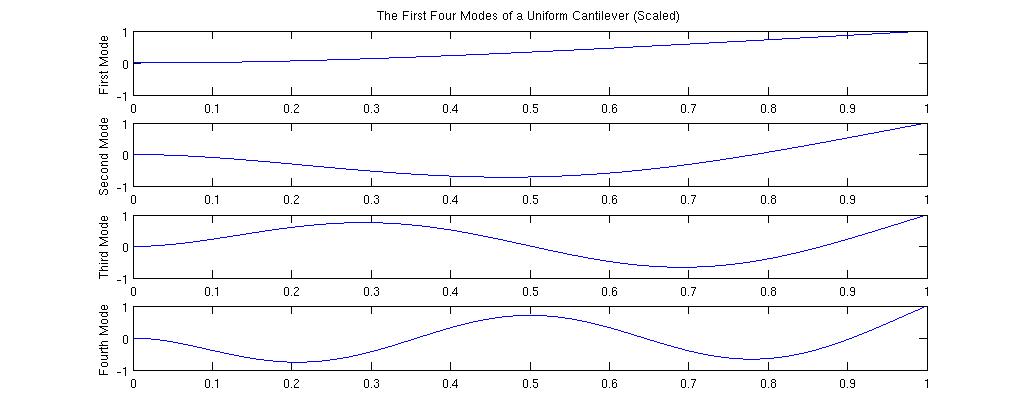

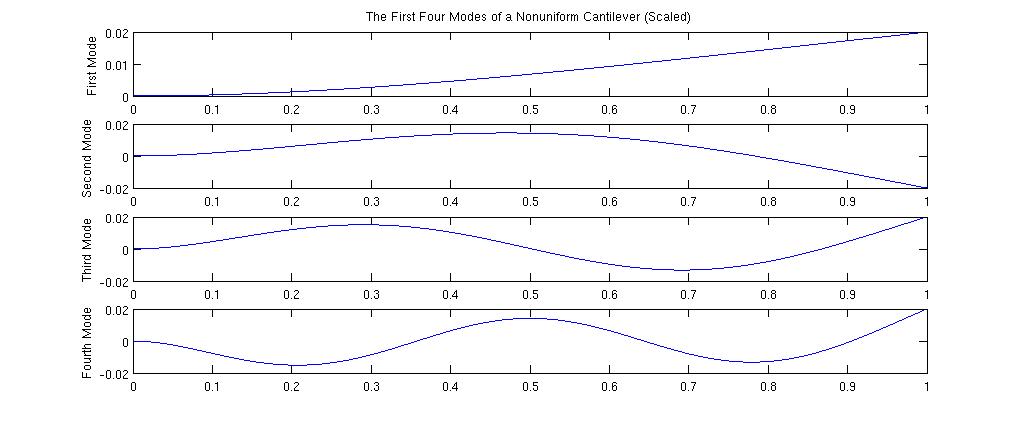

The diamond, when mounted from one corner, can be approximately modeled as a cantilever (a beam fixed at one end and free at the other) with non-uniform width. In order to determine the natural oscillatory motion of the diamond, I decided to develop a mathematical model for the motion of cantilevers with non-uniform width, and test that model with data from physical cantilevers.

Model

The cantilever system is best modeled by first considering the simplest version, a beam of uniform width, thickness, and height, fixed at one end and free at the other. It's possible to derive a fourth-order differential equation to describe the motion of a beam system by comparing the shear and torque on each height-wise section of the beam.

By assuming constant thickness, we can simplify this equation to something much more manageable.

Knowing that the motion of the beam will be oscillatory let's assume that the solution can be divided into two parts, one representing the maximum amplitude of the motion and the other representing the periodic nature of the motion.

We can now search for as an eigenfunction.

To see the process by which y_a is found, refer to the document embedded below.

Uniform-Width Analytical Model

To find the solution to the nonuniform case, we first express the solution as a linear combination of the solutions to the uniform case.

We know that the solutions to the uniform case, as the eigenfunctions of a Hermitian matrix operation, are orthogonal. This means that taking the inner product of any one of these solutions with any other solution is the equivalent of the kronecker delta .

To see the process by which the coefficients corresponding to the uniform case solutions are found, refer to the document embedded below.

Nonuniform-Width Analytical Model

Experiment

Materials

Fifteen test cantilevers of varying shapes cut from .032 inch thick sheet aluminum were used as experimental units to compare to the predicted results. (Cantilever construction was performed by Brendan Pratt in the UConn metal-working shop.)

- Nine cantilevers of uniform width (rectangular shape)

- Six cantilevers of non-uniform width linearly dependent on the length (diamond shape)

Methods

- Step 1: Location of Resonance Frequencies

Analysis was run in order to find the exact locations of the resonance frequencies for each individual cantilever. The cantilevers were mounted horizontally one at a time using a clamp to hold them fixed from one end. A microphone was set up near the tip of the cantilever, at an approximate distance of three centimeters away. The cantilever was then given a short, non-periodic impulse (a flick near the end) and allowed to settle into its natural oscillatory frequencies undisturbed. The microphone picked up the compressed air waves made by the cantilever’s vibration. This process was repeated three times for each cantilever. From this data the resonance frequencies were extracted using Fourier analysis.

- Step 2: Measuring Relative Amplitude:

The optical lever technique was used to determine the relative amplitude of cantilever vibration at different points along the length. Each cantilever was mounted in the same fashion as before, and the clamp was attached to a ring stand. Also attached to the ring stand was another clamp holding a small speaker. Resonance was achieved by using the speaker to produce a constant sinusoidal output, which traveled through the ring stand to excite the cantilever. A class 111a laser pointer was mounted opposite the free end of the cantilever, pointing towards the fixed end. A white projection screen was mounted above the fixed end of the cantilever. In order to amplify the motion of the cantilever, which is normally very slight, the laser is reflected off the cantilever’s surface, and its own angle of motion is augmented by that of the cantilever relative to the horizontal at the point of reflection.

To further increase this amplification, a system of mirrors was designed so that the laser would reflect off the cantilever multiple times over the same small lengthwise distance, multiplying the measured change in amplitude by the number of “bounces.” After coming out from the mirror system the laser projects onto the screen, where its sinusoidal motion reflects that of the cantilever. The motion of the laser point (keeping the number of bounces constant) was recorded at 1200 frames per second using a Casio Exilim Pro EX-F1 Digital Camera for each point along the length, moving at approximately one centimeter increments and recording the position of the center mirror relative to the cantilever base.