Using Fly Cutter

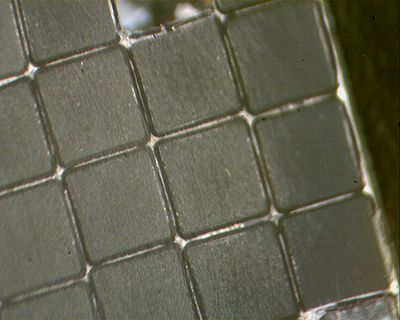

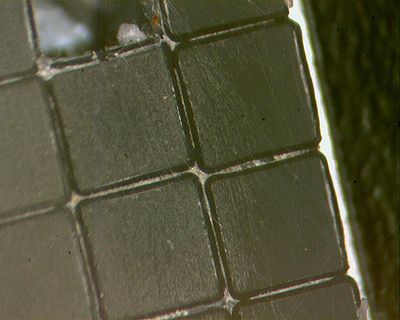

The Fly Cutter is a milling tool used to shave away layers of a flat surface. For our purposes, the fly cutter is used to cut several fibers at the same time leaving the fiber's ends with a flat and even surface. We designed a "angle clamp" to bundle the fibers together so that we can cut a 5x5 set of fibers with the fly cutter. In the picture to the right, we see the fibers bundled in the angle clamp, the angle clamp itself is attached to a metal piece used to mount the angle clamp in the fly cutter machine. With the fibers secured in the angle clamp, we set the bundle through a few test runs with the fly cutter to determine how fast the blade needs to spin the cut the fibers properly. A rotation speed of 1500 rpms was deemed to produce the best results. In the picture below, we see the fibers after being cut by the fly cutter. Notice the fiber's ends have many small scratches in them but I am confident that those scratches will easily be removed with just a quick polish.

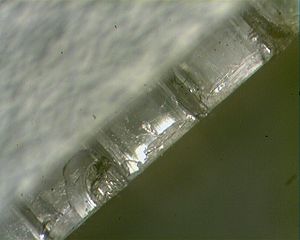

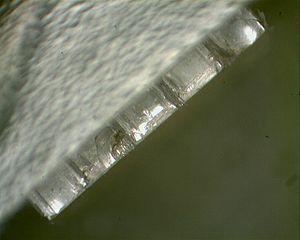

Something that was expected to happen was flaying or stripping of the outer most fiber's cladding. The picture on the right shows a close up view of the outer fibers, on the left a zoomed out view of the same fibers. The cladding is not damaged on all the outer fibers but it is stripped on the majority. All though there was noticeable damage to the cladding, I was surprised to see how well the cladding faired.

The machinists who cut the bundled fibers gave warning about a consequence of using the fly cutter. That is, the interior fibers would become slightly recessed. After a brief test it was determined that the fibers were not recessed significantly enough to be measured by our equipment (i.e the recession would be less then 0.0001 mm off from the plane. Therefore, any recession will not affect any part of the Tagger construction or performance.