Difference between revisions of "Fiber Polishing Procedure"

(Adding some tips on polishing) |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | Micah Warren | August 21, 2017 | ||

| + | |||

| + | ==General guidelines== | ||

| + | In all cases, the bundle should be kept near the center of the grinding wheel. This makes it easier to control the bundle, because the wheel isn’t on quite straight, and it wiggles less at the center than at the sides. Always use gentle pressure when holding the bundle against the wheel, just enough to keep it touching the wheel. Even gentler pressure is helpful when using finer grits, so little that the fibers may not even always touch the wheel, because of the wobble of the wheel: as the wheel makes one revolution, it grinds the fibers with the part of the wheel slanted toward them and misses them with the part slanted away. The fibers really do look better after a little time with gentle pressure, because the grit doesn’t dig in as deep. On the plastic grits (at least the five micron grit), it can be helpful to move the bundle around a little bit on the wheel, so as to grind the bundle in different directions. This helps remove striations. | ||

| + | |||

| + | |||

| + | As you polish, be sensitive to the feel and sound of the fibers on the wheel. If the wheel gently brushes up against the fibers, that is a good sign, but there should be no gritty feel or sound. If you do sense dust on the sandpaper, canned air can help clean the sandpaper off. It is also useful to realize that as you use the sandpaper, it gets filled up with plastic dust, and in the case of the plastic grits, worn down. This makes it less effective, which can help you achieve a nice shine; but if you need to sand down a significant amount and it is going slowly, consider replacing the sandpaper. | ||

| + | |||

| + | ==Light Guides== | ||

| + | |||

| + | The light guides should be bundled so that they stick out of the end collar by 0.1 inch. | ||

| + | |||

| + | ===For the fuse (upstream, non-elastic) end=== | ||

| + | *400 grit: take off whatever you need in order to bottom out to the 14-16 thousandths of an inch feeler gauge. Use speed 30 on the grinding wheel. | ||

| + | *1000 grit: take off ~8 thousandths of an inch, to bottom out to the 8 thousandths of an inch feeler gauge. When you are near the end, be sure to use just extra gentle pressure. By the end, the bundle should have only fine striations, and even those should be glossy. Speed 15 is good. | ||

| + | *5 micron: take off about whatever you need to make the bundle look smooth and shiny (maybe 3 thousandths of an inch). Use speed 15. | ||

| + | *Paper: just for a couple minutes. Speed 15 is good; be gentle and center the bundle. Only use paper if the fibers don’t look good enough after the five micron grit. (Sometimes you can even get away without using even the five micron grit.) The bundle should be nice and shiny, with minimal striations. | ||

| + | |||

| + | ===For the SiPM (downstream, elastic) end=== | ||

| + | All the techniques are the same as for the upstream end; only the distances change: | ||

| + | *400 grit: take off whatever you need in order to bottom out to the 16 thousandths of an inch feeler gauge. Use speed 30 on the grinding wheel. | ||

| + | *1000 grit: take off 8 thousandths of an inch, to bottom out to the 8 thousandths of an inch feeler gauge. When you are near the end, be sure to use just extra gentle pressure. By the end, the bundle should have only fine striations, and even those should be glossy. Speed 15 is good. | ||

| + | *There’s no need to use a feeler gauge with the rest of the grits. Just polish with each grit until it looks like the bundle is a good as that grit will get it. | ||

| + | |||

| + | |||

| + | ==Scintillating Fibers== | ||

| + | [This has yet to be written. For now, see the [[https://docs.google.com/document/d/1lTzhqt9KMahyBxVGTfyB8EtZjd1UG3V5iKoimt5Nie4/edit?usp=sharing preliminary polishing information]].] | ||

| + | |||

| + | |||

| + | =Old Procedure (Used Before Summer '17)= | ||

==Overview== | ==Overview== | ||

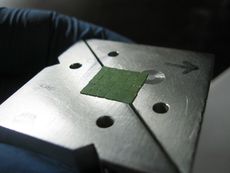

The non fused ends of each fiber must be polished to a mirrored finish. This allows the greatest amount of light transmission through the end of the fiber. Fibers are polished in their appropriate collars, SciFis in their 6x6 collar and light guides in their 5x6 collar. Polishing bundled fibers in their collars affords a number of advantages, the main ones being square fiber ends and minimal cladding flaring. Because the fibers are polished in their collars, it is important that the fiber ends are flush with one another. The scintillating fibers are easily made flush in their collar, but with light guides it is not so easy. For this reason, the light guides are polished as soon as they are returned from end-milling and while they are still in their collars. | The non fused ends of each fiber must be polished to a mirrored finish. This allows the greatest amount of light transmission through the end of the fiber. Fibers are polished in their appropriate collars, SciFis in their 6x6 collar and light guides in their 5x6 collar. Polishing bundled fibers in their collars affords a number of advantages, the main ones being square fiber ends and minimal cladding flaring. Because the fibers are polished in their collars, it is important that the fiber ends are flush with one another. The scintillating fibers are easily made flush in their collar, but with light guides it is not so easy. For this reason, the light guides are polished as soon as they are returned from end-milling and while they are still in their collars. | ||

Latest revision as of 03:20, 20 January 2018

Micah Warren | August 21, 2017

General guidelines

In all cases, the bundle should be kept near the center of the grinding wheel. This makes it easier to control the bundle, because the wheel isn’t on quite straight, and it wiggles less at the center than at the sides. Always use gentle pressure when holding the bundle against the wheel, just enough to keep it touching the wheel. Even gentler pressure is helpful when using finer grits, so little that the fibers may not even always touch the wheel, because of the wobble of the wheel: as the wheel makes one revolution, it grinds the fibers with the part of the wheel slanted toward them and misses them with the part slanted away. The fibers really do look better after a little time with gentle pressure, because the grit doesn’t dig in as deep. On the plastic grits (at least the five micron grit), it can be helpful to move the bundle around a little bit on the wheel, so as to grind the bundle in different directions. This helps remove striations.

As you polish, be sensitive to the feel and sound of the fibers on the wheel. If the wheel gently brushes up against the fibers, that is a good sign, but there should be no gritty feel or sound. If you do sense dust on the sandpaper, canned air can help clean the sandpaper off. It is also useful to realize that as you use the sandpaper, it gets filled up with plastic dust, and in the case of the plastic grits, worn down. This makes it less effective, which can help you achieve a nice shine; but if you need to sand down a significant amount and it is going slowly, consider replacing the sandpaper.

Light Guides

The light guides should be bundled so that they stick out of the end collar by 0.1 inch.

For the fuse (upstream, non-elastic) end

- 400 grit: take off whatever you need in order to bottom out to the 14-16 thousandths of an inch feeler gauge. Use speed 30 on the grinding wheel.

- 1000 grit: take off ~8 thousandths of an inch, to bottom out to the 8 thousandths of an inch feeler gauge. When you are near the end, be sure to use just extra gentle pressure. By the end, the bundle should have only fine striations, and even those should be glossy. Speed 15 is good.

- 5 micron: take off about whatever you need to make the bundle look smooth and shiny (maybe 3 thousandths of an inch). Use speed 15.

- Paper: just for a couple minutes. Speed 15 is good; be gentle and center the bundle. Only use paper if the fibers don’t look good enough after the five micron grit. (Sometimes you can even get away without using even the five micron grit.) The bundle should be nice and shiny, with minimal striations.

For the SiPM (downstream, elastic) end

All the techniques are the same as for the upstream end; only the distances change:

- 400 grit: take off whatever you need in order to bottom out to the 16 thousandths of an inch feeler gauge. Use speed 30 on the grinding wheel.

- 1000 grit: take off 8 thousandths of an inch, to bottom out to the 8 thousandths of an inch feeler gauge. When you are near the end, be sure to use just extra gentle pressure. By the end, the bundle should have only fine striations, and even those should be glossy. Speed 15 is good.

- There’s no need to use a feeler gauge with the rest of the grits. Just polish with each grit until it looks like the bundle is a good as that grit will get it.

Scintillating Fibers

[This has yet to be written. For now, see the [preliminary polishing information].]

Old Procedure (Used Before Summer '17)

Overview

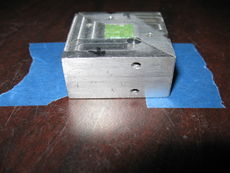

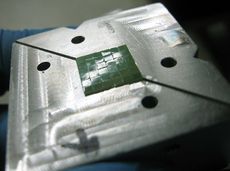

The non fused ends of each fiber must be polished to a mirrored finish. This allows the greatest amount of light transmission through the end of the fiber. Fibers are polished in their appropriate collars, SciFis in their 6x6 collar and light guides in their 5x6 collar. Polishing bundled fibers in their collars affords a number of advantages, the main ones being square fiber ends and minimal cladding flaring. Because the fibers are polished in their collars, it is important that the fiber ends are flush with one another. The scintillating fibers are easily made flush in their collar, but with light guides it is not so easy. For this reason, the light guides are polished as soon as they are returned from end-milling and while they are still in their collars.

Pre-Polishing Procedures

- Clean the table that you will be polishing fibers on. Any dust, sand, or dirt on the table will translate through the paper and scratch the fibers.

- Set out 2-4 pieces of clean copier paper or index card paper in a stack, and tape them to the table on each corner.

Light Guide Fibers

- Don a pair of gloves.

- If polishing recently end-milled light guides, find the side that has the most fibers flush with one another. This is the side you will polish.

- Note: the end-milling process cuts the fibers about .5 mm from the end of the collar. This half of a millimeter protrusion of fibers will allow the fibers to make contact with the paper instead of the aluminum collar, allowing the fibers to be polished. This protrusion is an artifact of the end-milling process, and should be taken full advantage of.

- Remove the collar from the end of the fibers that is not being polished.

- Place the collar square on the paper and support the other end of the light guide fibers by holding them above your head for the entirety of the polishing process.

Scintillating Fibers

- Don a pair of gloves.

- If polishing scintillating fibers, select the bag from the dark box with the bundle of fibers to be polished.

- Determine which end of the fibers has the flattest end-mill cut. This is the side that will be polished.

- Place the fibers carefully in their 6x6 collar, making sure that the fibers are square.

- Because these fibers have not just been end-milled, the person polishing the fibers will re-create the ~.5 mm protrusion of the fibers from the collar edge so that they may be polished.

- Place two .5 mm spacers underneath the collar but not underneath the fibers.

- Loosen the collar so that the fibers fall to the table while the collar is being supported by the spacer.

- Push on each individual fiber with a gloved finger, ensuring that the fiber end makes contact with the table.

- Without moving the collar, tighten it so that the fibers no longer move inside.

- Look at the table side of the fibers.

- If they are flush with one another they are ready to be polished.

- If they do not all look flush with each other, repeat the process with the spacers above until a relatively smooth polishing surface is achieved.

| ] |

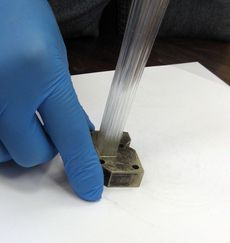

Polishing

- Begin making small circular movements with the collar on the paper while applying even pressure downwards.

- After a while the paper will become smooth and its polishing properties will decrease. When this occurs start to slowly move to another portion of the paper.

- Once the complete surface area of the polishing paper has been used the top sheet may be removed to expose the under sheet.

- Note: Maintain at least two (and no more than four) sheets of paper on the table at a time. Too few or too many sheets can result in possible cladding damage.

- Continue polishing until a mirrored surface is achieved.

- If a fiber slips in the collar and is no longer flush with the other fibers it may need to be polished individually using the Individual Polishing Puck.

- If this is the case, continue polishing until the other fibers in the bundle are polished.

- After a mirror finish is achieved for an entire bundle, it should be labeled and put in the appropriate area of the intermediate storage box.

- Polished ends of light guides should all face to the left in the dark box as consistent storing of polished fibers helps to save time during the fusing process.

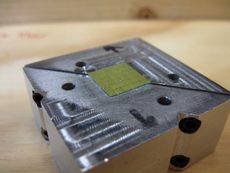

Individual polishing puck

If, while polishing in the collars, one or more of the fibers does not seem to be making contact with the paper, continue polishing the bundle until the other fibers are polished. The individual polishing puck does not create as good as a polish as is created when polishing a bundle, so only use the individual polishing puck as a last resort.

- Remove the fibers you need to polish individually from the bundle.

- Put the side to be polished through the single square hole in the individual polishing puck.

- With the side to be polished protruding the slightest bit (about .5 mm), hand tighten down the screw that holds the fiber in place.

- Adjust the side screws until the fiber is perpendicular to the base of the polishing puck.

- A very small protrusion and a perpendicular fiber help ensure that rounded edges are kept to a minimum and the fiber has a square polished face.

- Apply less pressure on the individual polishing puck than you used to polish a bundle. Too much pressure can bend or break the fiber.

- Continue to polish using small circles. Check the fiber end frequently as the time required to polish one fibers is much less than the time required to polish an entire bundle.

- While polishing, be sure to support the rest of the fiber so that it does not kink.

- Put the now polished fibers with the rest of the polished bundle, label it, and put it in the intermediate storage box, polished side to the left.