Difference between revisions of "Calibration Device for Scintillators"

(→To Do) |

|||

| Line 1: | Line 1: | ||

| − | + | Atoms contain nuclei that are made up of protons and neutrons which are comprised of quarks. These quarks are confined inside protons and neutrons by powerful bonds that are generated by the strong nuclear force of attraction between them. Particle physicists visualize these bonds as “channels” that form between the quarks, over which they continuously exchange virtual particles known as gluons. A new particle physics experiment, GlueX, is being constructed at the Thomas Jefferson National Accelerator Facility (Jefferson Lab) in Newport News Virginia, with the capability to excite the gluonic bonds between quarks and study their dynamics. | |

| + | |||

| + | To do this, the GlueX experiment requires a beam of polarized light (photons) with a very short wavelength, in the gamma ray spectrum. This beam of polarized photons is created by passing high-energy electrons from the Jefferson Lab accelerator through an oriented diamond crystal, such that they emit coherent bremsstrahlung radiation. The energy of each photon in the beam is “tagged” by detecting the electron that produced it in a scintillating fiber array called the tagging microscope. | ||

| + | |||

| + | '''To calibrate the tagging microscope, a source mounted on a linear motion stage has been designed and fabricated. The design, assembly and initial tests of this system is described.''' | ||

== Ideas == | == Ideas == | ||

| Line 5: | Line 9: | ||

*Worm gear connected to DC motor with micro controller set up | *Worm gear connected to DC motor with micro controller set up | ||

*Linear Rail system | *Linear Rail system | ||

| − | + | '''Stepper Motor Belt System was chosen''' | |

| − | ==Printer's Linear Motion== | + | ====Printer's Linear Motion==== |

*Disassembled printer casing | *Disassembled printer casing | ||

*Installed cygwin on computer for C interface and read up on programming language C | *Installed cygwin on computer for C interface and read up on programming language C | ||

| Line 16: | Line 20: | ||

*Unsuccessfully accessed printer | *Unsuccessfully accessed printer | ||

| − | ==Worm Gear== | + | ====Worm Gear==== |

*Spinning a long grooved metal cylinder gear requires a lot of torque | *Spinning a long grooved metal cylinder gear requires a lot of torque | ||

*Minimal support for head motion | *Minimal support for head motion | ||

*DC motor with time steps is not as effective as stepper motor | *DC motor with time steps is not as effective as stepper motor | ||

| − | ==Rail System== | + | ====Rail System==== |

*Has internal motion control | *Has internal motion control | ||

| − | * | + | *Very costly |

*Too heavy duty for this application | *Too heavy duty for this application | ||

| − | == Belt System == | + | == Belt System == |

*Stepper motor with micro controller stands stationary on one end and calibration device would be connected to a slide rail system for stability[[File:Gears 01.gif|thumb|Clamping Plate Setup http://www.polytechdesign.com/images/gears_01.gif]] | *Stepper motor with micro controller stands stationary on one end and calibration device would be connected to a slide rail system for stability[[File:Gears 01.gif|thumb|Clamping Plate Setup http://www.polytechdesign.com/images/gears_01.gif]] | ||

*We need to find something that is low cost but is accurate enough to be stopped at each fiber array block. Because the intended light source for calibration is most likely going to have a wide range, the step size does not have to be too small. | *We need to find something that is low cost but is accurate enough to be stopped at each fiber array block. Because the intended light source for calibration is most likely going to have a wide range, the step size does not have to be too small. | ||

| Line 43: | Line 47: | ||

==To Do== | ==To Do== | ||

*Design calibrating source on top of cart | *Design calibrating source on top of cart | ||

| + | *Integrate rotary encoder in labview program | ||

==Resources== | ==Resources== | ||

Revision as of 17:51, 5 May 2011

Atoms contain nuclei that are made up of protons and neutrons which are comprised of quarks. These quarks are confined inside protons and neutrons by powerful bonds that are generated by the strong nuclear force of attraction between them. Particle physicists visualize these bonds as “channels” that form between the quarks, over which they continuously exchange virtual particles known as gluons. A new particle physics experiment, GlueX, is being constructed at the Thomas Jefferson National Accelerator Facility (Jefferson Lab) in Newport News Virginia, with the capability to excite the gluonic bonds between quarks and study their dynamics.

To do this, the GlueX experiment requires a beam of polarized light (photons) with a very short wavelength, in the gamma ray spectrum. This beam of polarized photons is created by passing high-energy electrons from the Jefferson Lab accelerator through an oriented diamond crystal, such that they emit coherent bremsstrahlung radiation. The energy of each photon in the beam is “tagged” by detecting the electron that produced it in a scintillating fiber array called the tagging microscope.

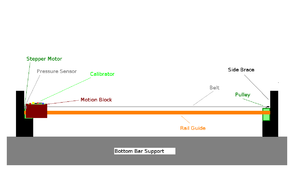

To calibrate the tagging microscope, a source mounted on a linear motion stage has been designed and fabricated. The design, assembly and initial tests of this system is described.

Ideas

- Printer disassembly and take-over of printer head linear motion through use of parallel port programming with C

- Worm gear connected to DC motor with micro controller set up

- Linear Rail system

Stepper Motor Belt System was chosen

Printer's Linear Motion

- Disassembled printer casing

- Installed cygwin on computer for C interface and read up on programming language C

- Investigated Computer Numerical Control but found it was not useful for this application

- Investigated serial port programming and the use of Printer Control Language on an HP printer documentation on PCL

Parallel Port Programming

- Interfacing directly to the printer proved very challenging [1]

- Unsuccessfully accessed printer

Worm Gear

- Spinning a long grooved metal cylinder gear requires a lot of torque

- Minimal support for head motion

- DC motor with time steps is not as effective as stepper motor

Rail System

- Has internal motion control

- Very costly

- Too heavy duty for this application

Belt System

- Stepper motor with micro controller stands stationary on one end and calibration device would be connected to a slide rail system for stability

Clamping Plate Setup http://www.polytechdesign.com/images/gears_01.gif

Clamping Plate Setup http://www.polytechdesign.com/images/gears_01.gif - We need to find something that is low cost but is accurate enough to be stopped at each fiber array block. Because the intended light source for calibration is most likely going to have a wide range, the step size does not have to be too small.

- For support: Overhead Enclosed-Track Conveyor Bracket, linear guide rail

Motor

- LinEngineering 1.8 Degree Motor 'WO-5718X-05E' was found to be appropriate and cost effective. [2]

Step Size

- With a LinEngineering 1.8 Degree Motor and a radius of .5" for the pulley, the step size would be 0.005" or 0.127mm which is well within a 2mm scintillator.

Beam Deflection

- The deflection at the center of the slide rail is calculated using a simply end supported beam as a model with beam deflection equations considering the weight of the bar and the weight of the cart. The maximum deflection was calculated as not exceeding 6um, well within the limit for our usage.

To Do

- Design calibrating source on top of cart

- Integrate rotary encoder in labview program