Difference between revisions of "Independent Study Final"

m (→Alcohol Test) |

m |

||

| Line 12: | Line 12: | ||

[https://docs.google.com/spreadsheet/ccc?key=0Au8hObtMJhV3dEo1MWp5MDg1M2ZqMm5BTlJrRkt1b1E&usp=sharing Alcohol Test Drive Document] | [https://docs.google.com/spreadsheet/ccc?key=0Au8hObtMJhV3dEo1MWp5MDg1M2ZqMm5BTlJrRkt1b1E&usp=sharing Alcohol Test Drive Document] | ||

| + | |||

| + | ==Strength Test== | ||

| + | |||

| + | [https://docs.google.com/a/uconn.edu/spreadsheet/ccc?key=0Au8hObtMJhV3dFZ4cUYtYXFJM2FIVG1ZVjBGOTZGU1E#gid=0 Strength Test Drive Document] | ||

Revision as of 20:30, 3 May 2013

By working in the lab with Ann Marie, I have learned a lot about the Tagger Microscope Construction project for Jefferson Lab. And my work regarding the project has been mostly testing the scintillating fibers and light guides during and after the fusing process. After covering the basic tasks of cutting and measuring fibers, I assisted Ann Marie in taking the data for the Alcohol Test, Strength Test, and Heat Test.

Alcohol Test

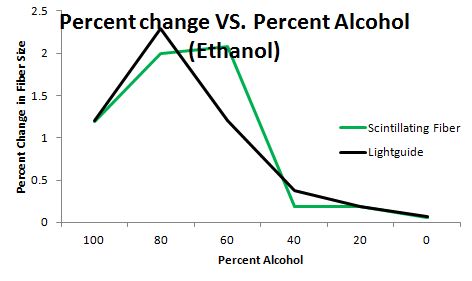

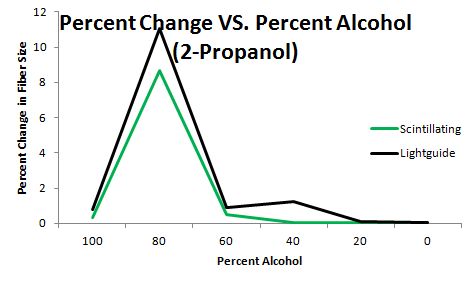

In this experiment, 10 Scintillating Fibers and 10 Light Guides were placed in varying solutions of either isopropyl alcohol or ethanol. Each fiber was cut and measured length-wise and width-wise before and after sitting in solution. The masses of the fibers were also recorded before and after.

Below are the graphs Ann Marie created. They show the percent change in fiber size vs. concentration of the solution (ethanol and isopropyl alcohol respectively). It is clear that some sort of chemical reaction or corroding effect is occurring when the fibers were set in 60% and 80% ethanol and 80% isopropyl. It is also worth noting that when measuring the fibers that had set in the previous solutions, the cladding of the fibers were very clearly coming off of the fibers.