Difference between revisions of "Microscope Electronics"

| Line 63: | Line 63: | ||

#*maximum noise P-P 5mV @ 1kHz < f < 5MHz | #*maximum noise P-P 5mV @ 1kHz < f < 5MHz | ||

#*maximum HF noise P-P 20mV @ f > 5MHz | #*maximum HF noise P-P 20mV @ f > 5MHz | ||

| − | #*long-term variation < & | + | #*long-term variation < ±10 mV |

# +5V for cmos logic VCC | # +5V for cmos logic VCC | ||

#*fixed 4.95V - 5.05V, no adjustment required | #*fixed 4.95V - 5.05V, no adjustment required | ||

| − | #* | + | #*#*maximum current 3A (15W power) |

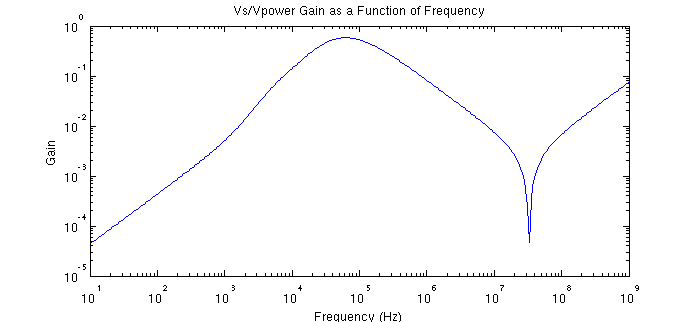

| − | + | The ripple specs for the 100V and the 6V power supplies are based on the two coupling curves shown below, for coupling from Vbias (top plot) and preamp VCC (bottom plot) into the output signal. | |

| − | The | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

[[file:FinalPreampVpowerGainCurve.png]] | [[file:FinalPreampVpowerGainCurve.png]] | ||

Revision as of 02:27, 5 December 2013

Electronics

The GlueX experiment will use a 9 GeV linearly polarized photon beam to search for mesons with gluonic excitations, and measure their spectrum and couplings. To create a well-collimated photon beam, the 12 GeV electron beam from CEBAF will pass through a 20um thick diamond wafer and undergo coherent bremsstrahlung. In order to know the energy of the photon the post-bremsstrahlung electron energy must be measured. A magnet is used to spatially separate the electrons corresponding to their energy which are incident on scintillating fibers. These fibers are located to provide 4 MeV energy resolution and propagate the signal to Silicon Photomultiplier (SiPM) counters that are mounted on custom high speed circuit boards. The scintillating fibers and electronics are housed in a light-sealed enclosure called the Tagger Microscope, which the research group at the University of Connecticut have designed to measure the post-bremsstrahlung electron energy, and therefore, the emitted photon energy.

Preamplifier

The purpose of the preamplifier is to receive signals from the scintillating fibers on the SiPMs and amplify the signal. These boards have two stages, the amplifying and summing circuits. In the first amplifying circuit the 15 SiPMs are individually amplified and can be independently readout. The summing circuit takes groups of 5 individual SiPM channels and sums the signals together into a summed output. This summing circuit also has the capability to change the gain of the amplified signal which allows for the study of cosmic rays and to see the dark rate of the SiPM.

[Note: Low gain mode is set to 5V and high gain mode is set to 10V]

Final Production

- Microscope Electronics Logbook - Alex Barnes

- Final Production Amplifier Logbooks

- Final production pdf containing the schematics and layer-by-layer Altium drawings

Preamplifier Version 2.0

- Preamp Version 2.0 Revision Notes

- SmartPDF of Preamp Version 2.0

- Picture of Preamp V2.0

- List of Board Changes

Digital Control Board

The control board is designed to regulate the bias voltages for the SiPMs and to communicate via ethernet to a remote computer. It is also designed to measure the temperature of the preamplifier and adjust the gain of the summing circuit of the preamplifier.

Final Production

- Final Production Control Board Logbooks

- Final production pdf containing the schematics and layer-by-layer Altium drawings

Backplane

The backplane is designed to be the intermediate board between the control and preamplifier boards. The preamplifier will be attached on the inside of the tagger microscope whereas the control board will be mounted outside. The backplane will allow signals to be sent between the other two boards as well as supply the power required to run all of the boards. The cable outputs for the SiPM signals are located on the backplane.

Final Production

- Final Production Backplane Logbooks

- Final production pdf containing the schematics and layer-by-layer Altium drawings

Power Supply Requirements

We require the following voltages on the boards:

- +100V (range 80V - 100V) for biasing

- 1V steps from 80V - 100V

- typical operation at 85V

- maximum current demand 500mA (50W power)

- maximum ripple P-P 50mV @ f < 1kHz

- maximum noise P-P 5mV @ 1kHz < f < 5MHz

- maximum HF noise P-P 20mV @ f > 5MHz

- long-term variation < ±50mV (0.05%)

- +6V (range 5.5V - 6.0V) for preamplifier VCC;

- 0.01V steps from 5.5V to 6.0V

- typical operation at 5.75V

- maximum current 8A (50W power)

- maximum ripple P-P 10mV @ f < 1kHz

- maximum noise P-P 5mV @ 1kHz < f < 5MHz

- maximum HF noise P-P 20mV @ f > 5MHz

- long-term variation < ±10 mV

- +5V for cmos logic VCC

- fixed 4.95V - 5.05V, no adjustment required

- maximum current 3A (15W power)

- fixed 4.95V - 5.05V, no adjustment required

The ripple specs for the 100V and the 6V power supplies are based on the two coupling curves shown below, for coupling from Vbias (top plot) and preamp VCC (bottom plot) into the output signal.

Hamamatsu MPPC SiPMs

- Pictures of the 35 Hamamatsu SiPMs

- Final Inspection Sheet Page 1

- Final Inspection Sheet Page 2

- Package and Pad layout

- Hamamatsu MMPC spec sheet

Pulse Generator

- Schematic of pulse generator, pg. 93

- Parts for pulse generator

- Picture of Pulse Generator

- Jon Kulakofsky's pulse generator fixing notes

Presentations