Difference between revisions of "Laser Images"

| Line 24: | Line 24: | ||

==Clarity== | ==Clarity== | ||

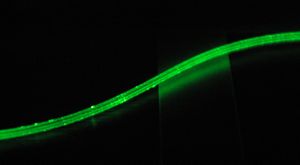

Freshly cut light guide demonstrates remarkable clarity and minimal light loss. These images illustrate the smoothness of an undamaged surface. | Freshly cut light guide demonstrates remarkable clarity and minimal light loss. These images illustrate the smoothness of an undamaged surface. | ||

| − | |||

| + | <gallery> | ||

| + | File:Exceptionally Clear New LG 0005.JPG|Figure4: Light Guide recently cut from spool shows exceptional clarity under laser light. | ||

| − | + | File:Open Shutter LG End DSC 0020.JPG|Figure 5: Polished end of light guide away from light source, recently cut from spool. Long exposure reveals minimal light loss relative to end. | |

| − | + | File:Bright Clear Nearly Perfect DSC 0019.JPG|Figure 6: Top view of light guide recently cut from spool. Uniform brightness indicates few surface abnormalities. | |

| + | </gallery> | ||

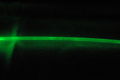

| + | ==Damage from Clamp== | ||

| + | <gallery> | ||

| + | File: Fast Shutter Clamp Damage DSC 0368.JPG|Figure 7 | ||

| + | File:Cropped DSC 0059.JPG|Figure 8 | ||

| − | + | File:Cropped detail clamp damage DSC 0061.JPG|Figure 9 | |

| − | + | </gallery> | |

| − | |||

| − | |||

| − | |||

| − | |||

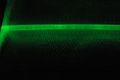

==Other Surface Imperfections== | ==Other Surface Imperfections== | ||

| + | <gallery> | ||

| + | File:Bright surface imperfections Cropped DSC 0030.JPG|Figure 10: Minimal surface imperfections visible near end of new light guide. | ||

| − | + | File:Cropped lower light edge imperfections DSC 0054.JPG|Figure 11: Imperfections along edge in new light guide. | |

| − | |||

| − | |||

| − | + | File:Cropped 2 surface some loss DSC 0056.JPG|Figure 12: Two sides of the wave guide are visible and minimal light loss is observed. Bright region due to laser angle. | |

| + | </gallery> | ||

Revision as of 23:16, 28 January 2016

Used Fibers

Light Loss Along Length

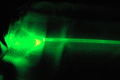

I took the segments of wave guide that I had examined under microscope and exposed them to a green laser pointer with very little ambient light. The laser illuminated the wave guide and revealed the effects of surface damage. Areas with fissures, dust, or residue sparkled under the green light. This indicates significant light loss. Understanding light loss is key to the success of the tagger microscope.

Surface Imperfections

Details of the damage are visible in these pictures.

Figure 2: In the upper right-hand third of the image are two parallel bands outlining a section of wave guide that seems brighter. This corresponds to the glue residue from the sticky labeling system. Other damage can also be seen.

Figure 3: Nicks, gouges, and residues coat the length of the fiber, causing light loss everywhere.

New Fibers

Clarity

Freshly cut light guide demonstrates remarkable clarity and minimal light loss. These images illustrate the smoothness of an undamaged surface.