LH Summer 2014

Revision as of 00:09, 26 June 2014 by Liana (talk | contribs) (→Results of Preliminary Fiber Tests)

This summer I worked primarily on Fiber QA. My daily work journal can be found here. I'll summarize my tests here.

Results of Preliminary Fiber Tests

Before we could run through all bundles through QA tests, we had to calibrate and standardize the QA testing procedure. We found the following sources of error:

- Laser Intensity - if the laser is brighter, each fiber will result in a higher photon yield. Dr. Jones has compensated for this. We also found that the photon yields decrease as the pulser's 9V battery is drained.

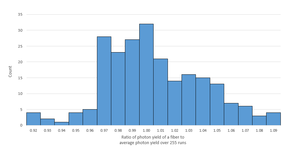

- Temperature of the SiPM board - we found that as the fiber runs were done repeatedly without turning off the electronics and removing the board, the photon yield decreases. Dr. Jones ran a script which automated the run process so that the runs had a certain amount of time in between. This histogram was made of 255 runs at approximately the same temperature (same time between runs) and compares each photon yield to the average over all runs.

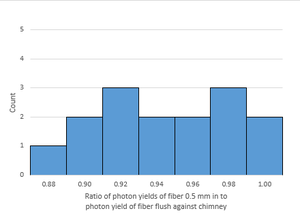

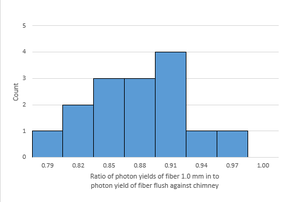

- Depth of the fibers in the chimney - We found that differences as small as 0.5 mm can have a minor affect on the photon yields. These histograms show the ratio of photon yields after a 0.5 mm or 1.0 mm fiber retraction to the photon yield while flush.

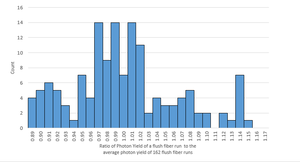

- Environmental Factors - I did a series of runs where between each run, I'd turn off the electronics, remove the SiPM board, remove the fibers and replace the fibers so they're flush. Here you can see the overall variation between a bunch of runs.