Hardware for Mounting of Diamond Radiators

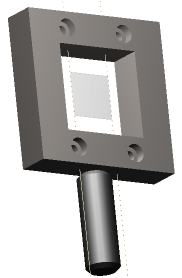

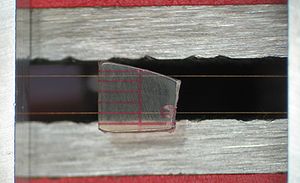

Mounting Bracket

The intended wire for clamping in this bracket is the 20 μm diameter tungsten wire borrowed from CMU. The bracket should have the planarity to handle this. Assuming elastic deformation of the bracket around the wires, force of order 100 N is expected, yielding to a force of friction well above the above the elastic limit of the wire (i.e. the wire will break before clamp releases it.)

Choice of Adhesives

Ellsworth Adhesives (Dist. Germantown, WI), Resinlab Cynergy Line:

- 6103 Metal Bonding Cyanoacrylate Adhesive [1]

- 6402 Toughened Cyanoacrylate Adhesive [2]

- Also available:

- AR 4305HP [5] (more general purpose, toluene-sensitive)

- 736 high temp. silicone sealant: 500F continuous use, degradation at 600F

Frank Murken Products (Dist. Schenectady, NY) (awaiting call)

Hernon Manufacturing, Inc. (Mfg. Sanford, FL) (in contact with Nicholas LaBarre)

- Supertacker 351 (easily dissolved with toluene etc.) [6]

- Silastomer 333

K.R. Anderson, Inc. (Dist.), Morgan Hill, CA

- Representative: nothing available

Master Bond, Inc. (Mfg.) (awaiting call)

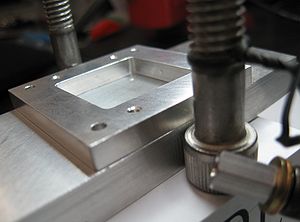

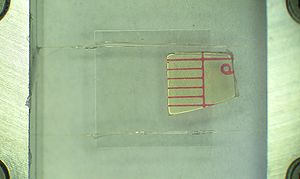

Diamond Mounting Trials

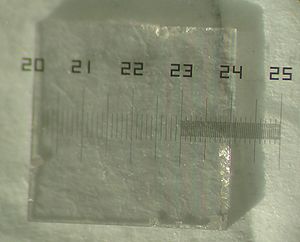

Simple wire stretching exercises were performed. The wire is approximated to have to be well past its elastic limit bearing 50 g weight. A thumb screw threading two washers going into a threaded stand-off (long nut) provided a nice 4.8 g weight that can clamp wire. So, a wire loop is created by clamping the ends of a wire segment between the washers by tightening the thumb screw.

The tungsten wire was stretched using this weight and the shanks of cap head screws to keep the segments parallel. Playing with the first setup showed that the wire breaks quite easily and indeed, breaks before there is enough force to release it from the clamp of the bracket. The experience also showed that the wire is easily denatured (observed through kinks present even when stretched) so care must be taken in taking it off the spool and navigating around the supports.