Fiber Water Stain Cleaning Procedure

Jump to navigation

Jump to search

Overview

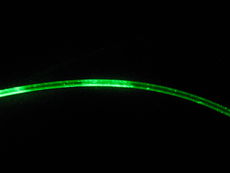

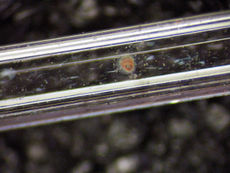

Cleanliness is important throughout the construction process. Of particular concern are the hard water stains left on the fibers after straightening and bending. Additionally, oils from the technician's skin may diminish the fibers' ability to retain and transmit light.

Procedures

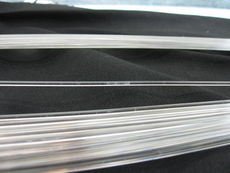

- Ensure that the table adjacent to the dark box is clean.

- Don a pair of gloves.

- To clean the fibers:

- Use a damp lint-free cloth and start from the center of each fiber, wiping to the end.

- Make certain to extend fully past the end of the fiber and not to drag the cloth back against the end of the fiber as this may cause the cloth to snag on the fiber and result in separation of cladding from the core.

- Repeat the previous step as many times as necessary, while using different sections of the cloth to ensure that each fiber is clean.

- Use a damp lint-free cloth and start from the center of each fiber, wiping to the end.

- Set each clean fiber in its place in the dark box.