Difference between revisions of "Fiber Water Stain Cleaning Procedure"

Jump to navigation

Jump to search

m (Jonesrt moved page Fiber Cleaning Procedure to Fiber Water Stain Cleaning Procedure: make it clear which generation of procedures is being deprecated) |

|||

| (5 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | ==Overview== | |

| − | Cleanliness is important throughout the construction process. Of particular concern | + | Cleanliness is important throughout the construction process. Of particular concern are the hard water stains left on the fibers after straightening and bending. Additionally, oils from the technician's skin may diminish the fibers' ability to retain and transmit light. |

| + | We have modified the procedures to ensure clean fibers. | ||

| + | * All fiber procedures require gloves to protect fiber from oils. | ||

| + | * A filtration system has been incorporated into the water system to minimize hard water stains. | ||

| + | * Fibers are cleaned after they have been removed from any water to prevent rust attaching to the fibers. | ||

| − | + | {|style="margin: 0 auto;" | |

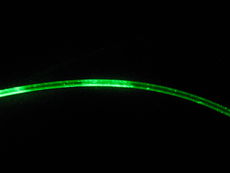

| + | | [[File:AMCFinger_Print_with_laser.JPG|thumb|upright|A spare fiber was touched with bare hands and illuminated from the inside with a green laser. The bright spots indicate escaping light due to the presence of oils.]] | ||

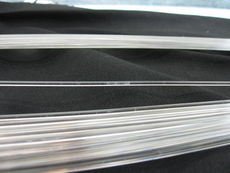

| + | | [[File:AMCBetter_Dust_SpotsJPG.JPG|thumb|upright|Accumulated dust buildup post-end milling but pre-cleaning.]] | ||

| + | || [[File:AMCBundle Pre-Clean.JPG|thumb|upright|A Bundle of fibers before being cleaned showing hard water stains.]] | ||

| + | | [[File:AMCHard_Water_Stains_Laser.JPG|thumb|upright|Laser shining through a fiber with hard water stains. Locations where light is escaping indicate presence of stains.]] | ||

| + | | [[File:Bundle Pre-Clean Laser.JPG|thumb|upright|A bundle of fibers before being cleaned with a laser shining through showing where hard water stains let light escape.]] | ||

| + | |} | ||

| + | |||

| + | {|style="margin: 0 auto;" | ||

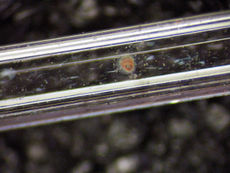

| + | | [[File:JK Rust Fiber 1.JPG|thumb|upright|Rust remaining on a fiber after coming out of the straightening rig.]] | ||

| + | | [[File:JK Rust Fiber 2.JPG|thumb|upright|Rust remaining on a fiber after coming out of the straightening rig.]] | ||

| + | | [[File:JK Rust Fiber 3.JPG|thumb|upright|A filter has been added to the input hose on the tank to soften the water, which should cut down on rust depositing on the fibers.]] | ||

| + | |} | ||

| + | |||

| + | ==Procedure== | ||

* Ensure that the table adjacent to the dark box is clean. | * Ensure that the table adjacent to the dark box is clean. | ||

* Don a pair of gloves. | * Don a pair of gloves. | ||

| − | + | * Use a clean, damp lint-free cloth and start from the center of each fiber, wiping to the end. | |

| − | + | ** Make certain to extend fully past the end of the fiber and not to drag the cloth back against the end of the fiber as this may cause the cloth to snag on the fiber and result in separation of cladding from the core. | |

| − | |||

** Repeat the previous step as many times as necessary, while using different sections of the cloth to ensure that each fiber is clean. | ** Repeat the previous step as many times as necessary, while using different sections of the cloth to ensure that each fiber is clean. | ||

* Set each clean fiber in its place in the dark box. | * Set each clean fiber in its place in the dark box. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Latest revision as of 16:49, 29 January 2016

Overview

Cleanliness is important throughout the construction process. Of particular concern are the hard water stains left on the fibers after straightening and bending. Additionally, oils from the technician's skin may diminish the fibers' ability to retain and transmit light.

We have modified the procedures to ensure clean fibers.

- All fiber procedures require gloves to protect fiber from oils.

- A filtration system has been incorporated into the water system to minimize hard water stains.

- Fibers are cleaned after they have been removed from any water to prevent rust attaching to the fibers.

Procedure

- Ensure that the table adjacent to the dark box is clean.

- Don a pair of gloves.

- Use a clean, damp lint-free cloth and start from the center of each fiber, wiping to the end.

- Make certain to extend fully past the end of the fiber and not to drag the cloth back against the end of the fiber as this may cause the cloth to snag on the fiber and result in separation of cladding from the core.

- Repeat the previous step as many times as necessary, while using different sections of the cloth to ensure that each fiber is clean.

- Set each clean fiber in its place in the dark box.