Fiber Testing Procedure

It is important to determine light yield of each fiber before shipment to Jefferson Lab. In order to do this, light yield tests will be performed on each fiber in our dark box using a red laser diode on a pulsing circuit. The setup of the fibers is very important, as any offset fibers could give an inaccurate result. It is also important that procedure is followed to prevent damage to electronics.

If the electronics are powered and the dark box is open, the siliconphotomultipliers WILL be damaged, so it is very important to make sure electronics are off before the dark box is opened.

Troubleshooting of the QA Procedure required multiple runs of the fibers. The results of those runs were motivations for changes to the testing procedure including: modification to the pulser circuit, modification to the pulser power source, standardized methods of placing the fibers into the chimneys, and consideration of temperature in analyzing photon yield. The results of these preliminary tests can be found below:

- Ann Marie's Troubleshooting Tests before the pulser circuit was modified

- Liana's Troubleshooting Tests after the pulser circuit was modified

- Liana's Work Journal and Liana's Summer Wiki Page accompany her Troubleshooting tests which describes more in-depth the thought process and steps behind each run.

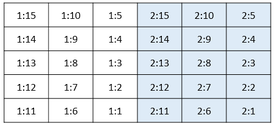

Fibers will be issued a new name after QA consisting of a Roman Numeral for the bundle which they are from, followed by a number in parentheses which designates it's position within the bundle. The diagram below shows how the fibers are positioned as viewed from the light guide/SiPM side of the fibers. These are also how the histos are going to appear in the analyzer.

Procedure

- Before taking any fibers out of the dark room, open the Fiber QA Google Doc. Each bundle has a separate tab which you can view the alignments required for each run.

- Before selecting fibers from their dark room, don a pair of powder free gloves and place the popsicle stick with the testing clamps at the table you will be working.

- Note which fibers are to be tested during the run and take only those fibers out of the dark room.

- If no meeting is going on in the conference room, bring the fibers in there and turn off all the lights.

- If someone is in the conference room, the clean room is a good alternative.

- Using the matrix in the spreadsheet as a guide, split the fibers in to the appropriate columns of 5 fibers each.

- Start with one column and put the fibers from that column in their appropriate order per the matrix on the spreadsheet. It is best to start with the offset 15 fibers first.

- Continue this process with the remaining columns.

- Once the fibers are in the order they belong, begin placing them in the clamp on the popsicle stick.

- This step will take two people. One person should place the fibers, while the other should hold them in place once they are placed. This way fibers will stay in their appropriate positions.

- Loosen the clamp and move it down over the fibers. Tighten it enough so they do not slip but not too tight as to make it impossible to add paper spacers in the near future. Also use the wires that are going through the holes in the popscile stick to your advantage. Tightening them around the fibers will do a good job of keeping the fibers in place.

- The fibers do not have to be flush with one another at this point. The next step, putting in paper spacers, will move them out of alignment anyways, so do not waste time on a step that will have to be repeated.

- To add paper spacers, use an index card and cut strips that are the width of the lines on the card. Then cut them into pieces that are about .5 inches long.

- The first set of paper spacers will go on the scintillating fiber end. Place strips of paper between each of the rows, and push them about an inch into the fiber. You will need to use any bit of paper that is sticking out of the sides to do this as you can't push between the rows themselves.

- Also place a strip of paper between the popsicle stick and the bottom row of fibers.

- Next, put strips of paper between each of the 3 columns. These strips of paper do not need to go far back, just far enough that they will not block any light from the pulser getting to the fiber face.

- The next step is to put spacers in the middle of the s-bend in the fibers for both columns and rows.

- Now it is time to make the face of the scintillating fibers flush with one another. This job also takes two people.

- One person should be holding a rigid piece of material along the popsicle stick where the fibers protrude while another person goes through each fiber and one by one pushes it in to the material.

- Once each fiber has been pushed into the rigid material, the fibers should be held in place by twisting the wire tightly around them. The rigid material should be carefully moved away to determine if the fibers are flush. If not, repeat the process again.

- After you are sure that the fibers are properly separated and flush with each other, make sure the wires and clamp is tight so that no fibers can change position.

- Check that all electronics are off before opening the dark box! Have a grad student or lab technician remove the board after opening the dark box. Carefully unscrew the main dark box opening and dock the popsicle stick into place by tightening the two screws underneath the popsicle stick to secure it into place. The wood has been depressed in the place where the popsicle stick should be. Do not modify the position of the pulsar at any point during the loading process!

- Guide the fiber ends over the edge and using the Google Document, place the fibers into the chimney in the correct order. Have a grad student or lab technician check the fibers at this step. The fibers cannot be too far into the chimneys or else they will damage the SiPMs when the board is replaced. A grad student or lab technician must put the SiPM board back into place.

- Let the black plastic divider down and Velcro the top opening shut so no light passes from the pulsar side to the SiPM side of the dark box.

- Close the main dark box opening and ensure that it is light sealed.

- Turn on the electronics and begin the fiber test.