Difference between revisions of "Fiber Polishing Procedure"

| Line 34: | Line 34: | ||

** If they do not all look flush with each other, repeat the process with the spacers above until a relatively smooth polishing surface can be achieved. | ** If they do not all look flush with each other, repeat the process with the spacers above until a relatively smooth polishing surface can be achieved. | ||

| − | [[File:JK SciFi Collar.JPG|thumb| | + | {|style="margin: 0 auto;" |

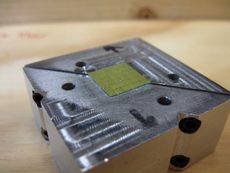

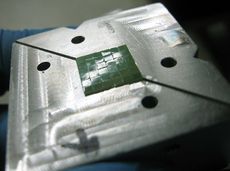

| + | | [[File:JK SciFi Collar.JPG|thumb|upright|An example of a bundle of scintillating fibers that has been setup for polishing.]]] | ||

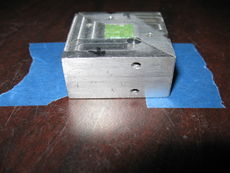

| + | | [[File:JK Scintillating Spacer.JPG|thumb|upright|The scintillating bundle positioned on its spacer, painter's tape in this case. The tape is positioned such that it sits underneath the collar but not underneath the fibers.]] | ||

| + | |} | ||

''Polishing'' | ''Polishing'' | ||

Revision as of 20:48, 19 May 2014

Overview The non fused ends of each fiber must be polished to a mirrored finish. This allows the greatest amount of light transmission through the end of the fiber. Fibers are polished in their appropriate collars, SciFis in their 6x6 collar and light guides in their 5x6 collar. Polishing bundled fibers in their collars affords a number of advantages, the main ones being square fiber ends and minimal cladding flaring. Because the fibers are polished in their collars, it is important that the fiber ends are flush with one another. The scintillating fibers are easily made flush in their collar, but with light guides it is not so easy. For this reason, the light guides are polished as soon as they are returned from end-milling and while they are still in their collars.

Procedures

- Clean the table that you will be polishing fibers on. Any dust, sand, or dirt on the table will translate through the paper and scratch the fibers.

- Set out 2-4 pieces of clean copier paper in a stack, and tape them to the table on each corner.

Light guide fibers

- If polishing recently end-milled light guides, find the side that has the most fibers flush with one another. This is the side you will polish.

- Note: the end-milling process cuts the fibers about .5 mm from the end of the collar. This half of a millimeter protrusion of fibers will allow the fibers to make contact with the paper instead of the aluminum collar, allowing the fibers to be polished. This protrusion is an artifact of the end-milling process, and should be taken full advantage of.

- Remove the collar from the end of the fibers that is not being polished.

- Place the collar square on the paper and support the other end of the light guide fibers by holding them above your head for the entirety of the polishing process.

- The light guide is now ready to polish.

Scintillating fibers

- If polishing scintillating fibers, select the bag from the dark box with the bundle of fibers to be polished.

- Determine which end of the fibers has the flattest end-mill cut. This is the side that will be polished.

- Place the fibers carefully in their 6x6 collar, making sure that the fibers are square.

- Because these fibers have not just been end-milled, the person polishing the fibers will re-create the ~.5 mm protrusion of the fibers from the collar edge so that they may be polished.

- Place two .5 mm spacers underneath the collar but not underneath the fibers.

- Loosen the collar so that the fibers fall to the table while the collar is being supported by the spacer.

- Push on each individual fiber with a gloved finger, ensuring that the fiber end makes contact with the table.

- Without moving the collar, tighten it so that the fibers no longer move inside.

- Look at the table side of the fibers.

- If they are flush with one another they are ready to be polished.

- If they do not all look flush with each other, repeat the process with the spacers above until a relatively smooth polishing surface can be achieved.

| ] |

Polishing

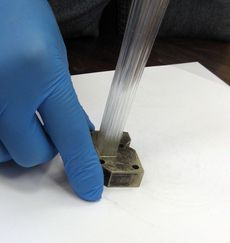

- Begin making small circular movements with the collar on the paper while applying even pressure downwards.

- After a while the paper will become smooth and its polishing properties will become reduced. When this occurs start to slowly move to another portion of the paper.

- Once the complete surface area of the polishing paper has been used the top sheet may be removed to expose the under sheet.

- Note: Maintain at least two (and no more than four) sheets of paper on the table at a time. Too few or too many sheets can result in possible cladding damage.

- Continue polishing until a mirrored surface is achieved.

- If a fiber slips in the collar and is no longer flush with the other fibers it may need to be polished individually.

- If this is the case, continue polishing until the other fibers in the bundle are polished.

- Take the collar apart and put the polished fibers to the side.

- The individual fiber will be polished with an individual polishing puck. The puck is designed to keep the fiber perpendicular to the page so as to achieve a square polish. However, polishing in collars does this better, and is therefore the preferred way to polish. The individual polishing puck should only be used when necessary.

- After a mirror finish is achieved for an entire bundle, it should be labeled and put in the appropriate area of the intermediate storage box.

- Polished ends of light guides should all face to the left in the dark box as consistent storing of polished fibers helps to save time during the fusing process.

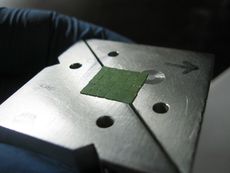

Individual polishing puck

- If, while polishing in the collars, one or more of the fibers does not seem to be making contact with the paper, continue polishing the bundle until the other fibers are polished, take the collar off, and use the individual polishing puck on the non polished fibers.

- Put the side to be polished through the single square hole in the individual polishing puck.

- With the side to be polished protruding the littlest bit (about .5 mm), hand tighten down the screw that holds the fiber in place.

- Adjust the side screws until the fiber is perpendicular to the base of the polishing puck.

- A very small protrusion and a perpendicular fiber help endure that rounded edges are kept to a minimum and the fiber has a square polished face.

- While polishing be sure to support the rest of the fiber so that it does not kink.

- Put the now polished fibers with the rest of the polished bundle, label it, and put it in the intermediate storage box, polished side to the left.