Difference between revisions of "Fiber Fusing Procedure"

| Line 15: | Line 15: | ||

|} | |} | ||

| − | * Inspect the splicing unit: Check | + | * Inspect the splicing unit: Check that the top sliding collar and compression block move smoothly and unencumbered. Check for cracks in the glass ferrules and ensure they are clean. Verify all peripheral equipment is in working order. Note any discrepancies to the lead technician prior to proceeding with the fusing process. |

{|style="margin: 0 auto;" | {|style="margin: 0 auto;" | ||

Revision as of 16:50, 9 June 2014

Overview

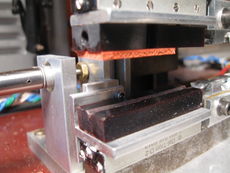

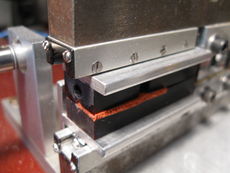

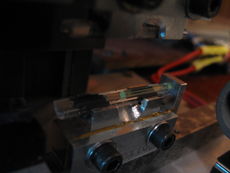

The joint between the SciFI and the light guide is one of the most critical points in the construction of the tagger microscope. Prior attempts to glue this joint with epoxy proved to be mechanically unreliable. A splicing unit has been procured from MSU and retrofitted for use with square fibers. Special order glass ferrules are used to maintain the fibers' shape while the union between the SciFi and light guide are heated to melting point.

Safety Information: During the fusing process, it is important to wear powder-free gloves and long sleeves (or a lab coat). Do not look at the light or near the fusing site while the lamp is turned on as it is extremely bright. Do not touch the fusing lamp ever, as it gets very hot and oil from skin will cause the lamp to break.

Procedure

- Power up the fusing unit by turning the two power switches on. Power up the compressor by plugging it into its designated electrical socket and flipping up the red switch on the compressor. When the compressor turns on, the pressure gauge reading should begin to increase.

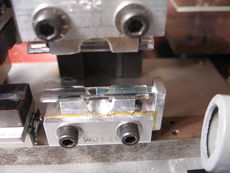

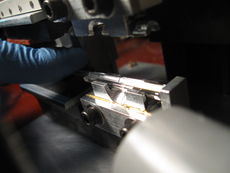

- Inspect the splicing unit: Check that the top sliding collar and compression block move smoothly and unencumbered. Check for cracks in the glass ferrules and ensure they are clean. Verify all peripheral equipment is in working order. Note any discrepancies to the lead technician prior to proceeding with the fusing process.

- After the compressor is done warming up, adjust the gauges so that the left pressure gauge is approximately 57 psi, and the right pressure gauge is approximately 95 psi.

- Before fusing, measure and record the cross-sections of both the SciFi and the light guide about to be fused. The SciFi's cross-sectional measurements should be taken at the center of the fiber, and the light guides measurements should be taken at the non-polished end. Also measure the SciFi's length using a caliper and record along with the cross-sectional measurements.

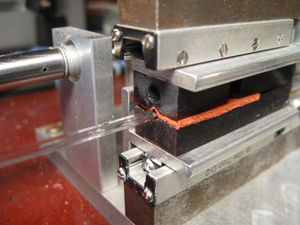

- With the splicing collars open, place a clean, straight, cut SciFi in the bottom glass ferrule. Make sure that the polished end of the SciFi is not the end about to be fused. Also ensure that the fiber is butted up against the collar stop on the right-hand side and that the fiber is oriented so that its sides lie flat against the sides of the glass ferrule.

- Place the non-polished end of the light guide into the bottom glass ferrule so that its sides lie flat against the sides of the ferrule. Make sure the light guide is far enough into the fusing unit such that the non-polished end of the light guide is touching the non-polished end of the SciFi.

- Loosely hold the light guide in place while hitting the "ON" button. Release the light guide as the automated fusing process clamps the top ferrule to the bottom ferrule.

- In the few seconds between when the collars clamp together and the light turns on, check the following:

- Ensure that the ferrules have clamped properly and the fibers are positioned in the correct orientation.

- Check again that the pressure gauges are at the appropriate pressures.

- Turn down the protective light shield. If there are any problems with this step, hit the "STOP" button to stop the fusing process.

- With the protective shield down and the lamp on, monitor the pressure gauges and watch the fusing process from behind the protective light shield. A line is visible at the junction of the two fibers and it should slowly disappear as the two fibers fuse. If there is an issue with the fusing process, hit the "STOP" button.

- After the fusing process is complete, the ferrules will become unclamped. Carefully remove the fused fibers and inspect the fuse joint. If the fibers do not appear to be completely fused, if there is a significant dimple in the fuse, or if there are air bubbles in the fuse joint, notify the lead technician.

- There will usually be a slight protrusion in the fiber where the ferrules meet due to flow in the melting plastic, however this is small and can be filed off with minimal damage to the cladding by carefully sanding only on the corners of the fuse site.

- If the fibers appear fused, measure and record both cross-sections of the fuse joint. Complete the fusing process for 30 fibers to complete a bundle.

- When a bundle is completed, turn off the fusing unit by turning the two power switches off. Underneath the fusing unit, decrease the pressure of the compressor and turn off the red switch which powers the compressor.