Fiber Array Fabrication Techniques

Tools

- We designed our own apparatus to cut, polish, and glue the scintillators and the waveguides. For more information on how it works, see Work Stand Assembly.

- To cut the fibers I use a standard hobby knife.

- For cleaning and polishing acrylic fibers, the recommended tool to use is a plastic nail buff.

- A digital scale (accurate to ±0.01 grams) is used to weigh out the proper proportions of the resin and catalyst.

- Standard laboratory glassware is used for weighing, mixing, and applying the epoxy.

- A laboratory hotplate is used to heat-cure the epoxy.

- An infrared thermometer is used for calibrating the hotplate temperature controls.

For more information (such as prices and product numbers) on the equipment listed above see Supplies

Fiber Research

Fiber Width Variation

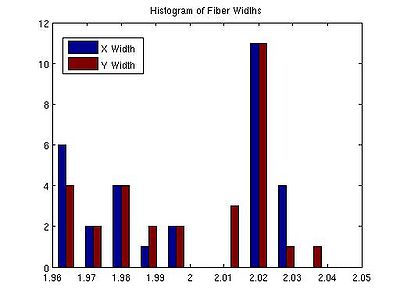

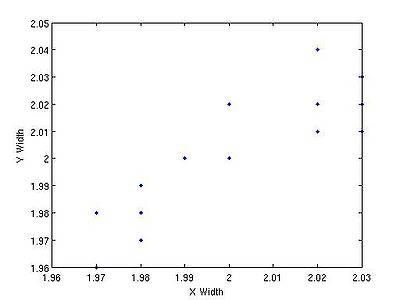

To make acrylic optical fibers, Bicron uses the stretch method which involves stretching a mass of material into a long fiber of a specific diameter or width in our case. As a result of this process, there develops minor variations in width along the stretched fiber. Since minor variations in width can compound in to a significant misalignment, I have measured the width distribution of 30 fibers cleaved from the same fiber spool. Below is a histogram of the widths and a plot of the x-axis width vs. the y-axis.

- Note: units of above graphs are millimeters

The results of the measurements revealed a standard deviation of x= 0.0269 y= 0.0244 and a mean of x= 1.9983mm y= 2.0000mm. These small deviations are insignificant and should not cause significant problems in the construction or functionality of the Tagger.

Epoxies

The epoxies that are being tested are:

- BC-600 (Bicron) BC-600 Info

- EJ-500 (Eljen Technology) EJ-500 Info

- 20-3238 (Epoxies Etc) 20-3238 Info

Cleaving and Polishing Techniques

Using Fly Cutter

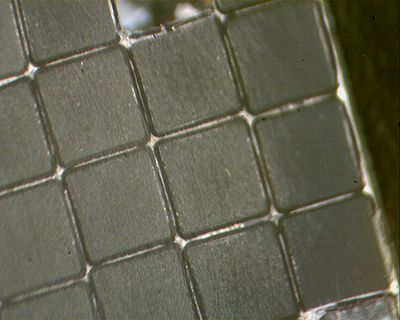

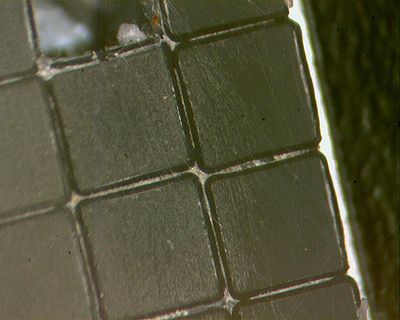

The Fly Cutter is a milling tool used to shave away layers of a flat surface. For our purposes, the fly cutter is used to cut several fibers at the same time leaving the fiber's ends with a flat and even surface. We designed a "angle clamp" to bundle the fibers together so that we can cut a 5x5 set of fibers with the fly cutter. In the picture to the right, we see the fibers bundled in the angle clamp, the angle clamp itself is attached to a metal piece used to mount the angle clamp in the fly cutter machine. With the fibers secured in the angle clamp, we set the bundle through a few test runs with the fly cutter to determine how fast the blade needs to spin the cut the fibers properly. A rotation speed of 1500 rpms was deemed to produce the best results. In the picture below, we see the fibers after being cut by the fly cutter. Notice the fiber's ends have many small scratches in them but I am confident that those scratches will easily be removed with just a quick polish.

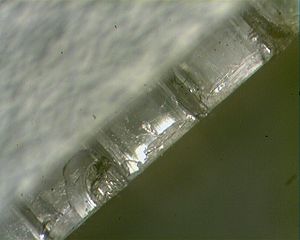

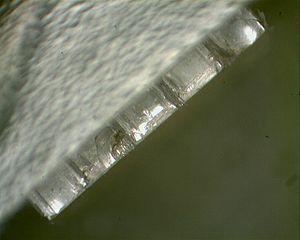

Something that was expected to happen was flaying or stripping of the outer most fiber's cladding. The picture on the right shows a close up view of the outer fibers, on the left a zoomed out view of the same fibers. The cladding is not damaged on all the outer fibers but it is stripped on the majority. All though there was noticeable damage to the cladding, I was surprised to see how well the cladding faired.

The machinists who cut the bundled fibers gave warning about a consequence of using the fly cutter. That is, the interior fibers would become slightly recessed. Therefore, brief testing will be done to determine if the inner fibers do in fact recess slightly.

Transmission Testing

The main question to be answered by testing the transmission rates is to determine how well we need to polish the fibers. This is done by cutting a 25.625” length of fiber into four segments, gluing those segments back together, testing in the dark box and comparing the results to the control fiber. The segmented fiber will be polished three different ways:

- The first is using only with the emery board leaving a rough polish

- The second adds the use of the three buffer boards

- The third adds stripping the cladding before polishing.

The reason for the multiple cuts of the fibers is to increase the loss of photons. The increased loss of photons will make it easier to identify small changes in the transmission rate between the fibers polished the three different ways.

- Note: This is only testing the relative transmission rates. All percentages of transmission loss is acquired by comparing to the control fiber. Also, the epoxy used for these tests is 20-3238.

- Current Results

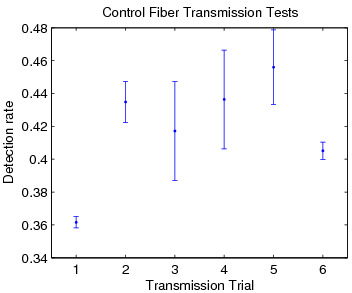

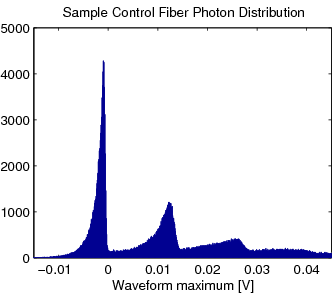

We tested the control fiber several times and each time we got a significantly different result. Below we see a histogram of the control fiber whose test length was about 48 hours and a graph comparing the different tests of the control fiber.

As you can see from the graph, there is a large discrepancy between the different tests of the contorl fiber. This could be caused by several things, such as

- The fiber end pointing to the SiPM changes position to dramatically

- The fiber end facing the LED changes position significantly as to change the amount of photons able to transmit through the fiber.

- In changing the fiber, the SiPM could have been disturbed.

- Solution to Problems

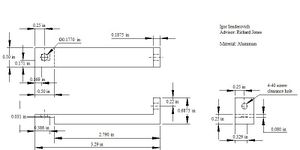

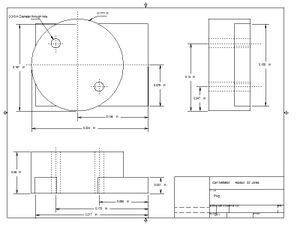

(Addressing the problems out of order) We redesigned the "thermal finger" for holding the two different SiPMs. The designs are seen below. The purpose for this is so that the SiPMs can be changed out easily and that we can ensure that the device is in the same position every time.

To ensure that that fiber is in the same position every time in the protochimney, we wrap the end of the fiber in electrical tape (even amounts on all sides). Once wrapped the fiber should fit snugly in the chimney thereby reducing the movement of the fiber. Addressing the remaining problem, we are still working on a proper solution.

Gluing

The gluing process is on-going, so there will be updates to this section.

- Setup:

- There is quite a bit to set up before you begin actually applying epoxy. To start, make sure you have the following supplies:

- Lab Gloves

- Kim wipes

- Digital scale

- Acetone and isopropanol

- A container to mix the epoxy, and a waste container

- The resin and catalyst (or hardener) of the epoxy

- A pipette with tip and dispensing pump

- Tongue depressors

- Once you have collected all the necessary equipment you can begin setting up for gluing. First and foremost, PUT ON GLOVES. Now, take out several kim wipes and place them under the digital scale, the waste container, the resin and catalyst, and on anything that could have unwanted chemicals spilled on. Set 3 or 4 tongue depressors and 3 or 4 pipettes off to the side of your workstation so that they are not in the way but easily accessible. Pour some acetone or isopropanol in your waste container for quick cleaning. Inspect all glassware to make sure that they are completely clean. If you find glassware that is not clean, clean it using acetone and then wait at least 10 minutes before using the glassware. Now that you are all set up you can begin gluing.

- There is quite a bit to set up before you begin actually applying epoxy. To start, make sure you have the following supplies:

Here is a picture of all the new equipment that is required for the new application process.

- Epoxy 20-3238

- Weigh out your resin and catalyst, this is a MAJOR factor in the success of the experiment so take your time in mixing and getting the exact amounts of resin and catalyst (100 parts resin to 30 parts catalyst).

- Once you have the two components weighed out, mix them together. The mixture should turn mildly opaque and become viscous. When the components are mixed completely, the mixture should turn clear and the viscosity should decrease a bit, becoming more like cooking oil in viscosity.

- There will be bubbles left in the mixture. To get rid of them, just let the mixture sit for about 10 or 15 minutes and the bubbles will come to the surface. Then gently pop the bubbles with a tongue depressor. Now since the pot life of epoxy is 40 to 45 minutes, you will have plenty of time to get rid of the bubbles.

- Once you have the mixed the epoxy, lay the fibers out in the apparatus how you want them to be glued together as shown in the picture to the left. Click on the picture to get a better look at the fibers. Make sure that the ends of the fibers are clean and polished before applying the epoxy. This can and should be done while you wait for the bubbles to escape from the epoxy.

- Now that you have the fibers set and ready to receive the epoxy, take a clean pipette with a dispensing pump and install a tip on the end of the pipette. It is not extremely easy to tell when a tip is completely attached to the end of the pipette, so practice installing pipette tips before running through the entire procedure for the first time.

- With the tip on the pipette, get a small amount of the epoxy in the pipette, and then inject it into the small gap between the two fibers. The final result should look like the picture seen to the right. Click on the photo to see a bigger image.

- Now that the epoxy has been applied, make the final adjustments to the fibers to make sure that they are at the distance desired and that they are lined up properly. All the adjustments should be minor ones, correcting any motion that occurred during the application process. Then let the epoxy cure for 18 to 24 hours at STP, or for 1 to 2 hours at 60 Celsius.

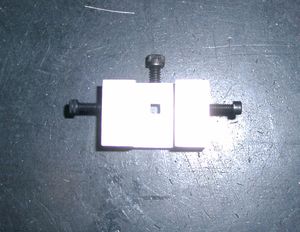

Protochimney

Note: This is not the prototype chimney to be used to couple the matrix of waveguides to the SiPMs. The "protochimney" is to be used in our dark box to couple one fiber to one SiPM. The purpose of this coupling is to test the transmission properties of cleaved fibers joined by different epoxies.

- Below are pictures of the completed protochimney.