Difference between revisions of "Hardware for Mounting of Diamond Radiators"

Senderovich (talk | contribs) |

Senderovich (talk | contribs) |

||

| Line 3: | Line 3: | ||

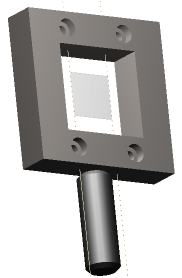

[[Image:DiaMountBracket.png|frame|Exploded view of the mounting bracket with the diamond shown suspended on stretched wires.]] | [[Image:DiaMountBracket.png|frame|Exploded view of the mounting bracket with the diamond shown suspended on stretched wires.]] | ||

| − | * Mounting Bracket: [http://zeus.phys.uconn.edu/~senderovich/GlueX/Diamonds/MountingBracket/DiaMountBracket.tcw TCW] | + | * Aluminum Mounting Bracket: [http://zeus.phys.uconn.edu/~senderovich/GlueX/Diamonds/MountingBracket/DiaMountBracket.tcw TCW] |

** Front Half: [http://zeus.phys.uconn.edu/~senderovich/GlueX/Diamonds/MountingBracket/DiaMountBracket_F.pdf PDF] [http://zeus.phys.uconn.edu/~senderovich/GlueX/Diamonds/MountingBracket/DiaMountBracket_F.tcw TCW] | ** Front Half: [http://zeus.phys.uconn.edu/~senderovich/GlueX/Diamonds/MountingBracket/DiaMountBracket_F.pdf PDF] [http://zeus.phys.uconn.edu/~senderovich/GlueX/Diamonds/MountingBracket/DiaMountBracket_F.tcw TCW] | ||

** Back Half [http://zeus.phys.uconn.edu/~senderovich/GlueX/Diamonds/MountingBracket/DiaMountBracket_B.pdf PDF] [http://zeus.phys.uconn.edu/~senderovich/GlueX/Diamonds/MountingBracket/DiaMountBracket_B.tcw TCW] | ** Back Half [http://zeus.phys.uconn.edu/~senderovich/GlueX/Diamonds/MountingBracket/DiaMountBracket_B.pdf PDF] [http://zeus.phys.uconn.edu/~senderovich/GlueX/Diamonds/MountingBracket/DiaMountBracket_B.tcw TCW] | ||

| + | |||

| + | The intended wire for clamping in this bracket is the 20 μm diameter tungsten wire borrowed from CMU. The bracket should have the planarity to handle this. Assuming elastic deformation of the bracket around the wires, force of order 100 N is expected, yielding to a force of friction well above the above the elastic limit of the wire (i.e. the wire will break before clamp releases it.) | ||

| Line 32: | Line 34: | ||

'''Master Bond, Inc.''' (Mfg.) | '''Master Bond, Inc.''' (Mfg.) | ||

(awaiting call) | (awaiting call) | ||

| + | |||

| + | |||

| + | == Diamond Mounting Trials == | ||

| + | |||

| + | [[Image:WireStretchTests.jpg|thumb|400px|Simple setup for testing wire stretching. Cap head bolts take the place of precise diameter rods that specify wire spacing. The ~5 g weight is shown on the right.]] | ||

| + | |||

| + | Simple wire stretching exercises were performed. The wire is approximated to have to be well past its elastic limit bearing 50 g weight. A thumb screw threading two washers going into a threaded stand-off (long nut) provided a nice 4.8 g weight that can clamp wire. So a wire loop is created by clamping the ends of a wire segment between the washers by tightening the thumb screw. | ||

| + | |||

| + | [[Image:MBWireMarks.jpg|thumb|400px|Photo of grooves embossed by the clamped tungsten wire. (Numbers indicate mm markings)]] | ||

Revision as of 14:23, 23 April 2009

Mounting Bracket

The intended wire for clamping in this bracket is the 20 μm diameter tungsten wire borrowed from CMU. The bracket should have the planarity to handle this. Assuming elastic deformation of the bracket around the wires, force of order 100 N is expected, yielding to a force of friction well above the above the elastic limit of the wire (i.e. the wire will break before clamp releases it.)

Choice of Adhesives

Ellsworth Adhesives (Dist. Germantown, WI), Resinlab Cynergy Line:

- 6103 Metal Bonding Cyanoacrylate Adhesive [1]

- 6402 Toughened Cyanoacrylate Adhesive [2]

- Also available:

- AR 4305HP [5] (more general purpose, toluene-sensitive)

- 736 high temp. silicone sealant: 500F continuous use, degradation at 600F

Frank Murken Products (Dist. Schenectady, NY) (awaiting call)

Hernon Manufacturing, Inc. (Mfg. Sanford, FL) (in contact with Nicholas LaBarre)

- Supertacker 351 (easily dissolved with toluene etc.) [6]

- Silastomer 333

K.R. Anderson, Inc. (Dist.), Morgan Hill, CA

- Representative: nothing available

Master Bond, Inc. (Mfg.) (awaiting call)

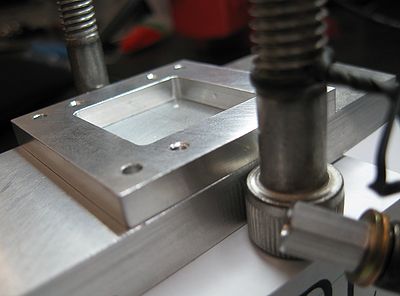

Diamond Mounting Trials

Simple wire stretching exercises were performed. The wire is approximated to have to be well past its elastic limit bearing 50 g weight. A thumb screw threading two washers going into a threaded stand-off (long nut) provided a nice 4.8 g weight that can clamp wire. So a wire loop is created by clamping the ends of a wire segment between the washers by tightening the thumb screw.