Difference between revisions of "Intermediate Storage Box"

| Line 1: | Line 1: | ||

=Construction= | =Construction= | ||

=Relining= | =Relining= | ||

| − | + | The first version of the light guide box was lined with a soft, stretchy fabric. However, this fabric produced a lot of lint, fouling the light guides, and making it difficult to weld the scintillating fibers and the light guides. So I (Micah Warren) relined it. | |

| − | + | We bought fifteen yards of a silky black cloth from Jo-Ann Fabrics. I lay it down in three panels from the front rim of the box, each panel lying along the bottom, to the hinge in the back, and up the lid to the rim again. Because the fabric did not come in one full, fifteen-yard piece, I was unable to do the rightmost panel with a single piece of fabric. I had to use two pieces. | |

| − | + | I used a staple gun to hold the fabric in place, and if a staple didn't go in far enough, I tapped it with a hammer. | |

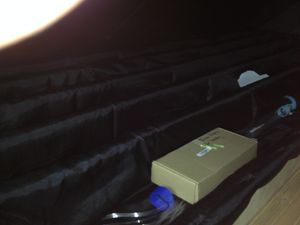

=Photos= | =Photos= | ||

Revision as of 16:18, 15 June 2017

Construction

Relining

The first version of the light guide box was lined with a soft, stretchy fabric. However, this fabric produced a lot of lint, fouling the light guides, and making it difficult to weld the scintillating fibers and the light guides. So I (Micah Warren) relined it.

We bought fifteen yards of a silky black cloth from Jo-Ann Fabrics. I lay it down in three panels from the front rim of the box, each panel lying along the bottom, to the hinge in the back, and up the lid to the rim again. Because the fabric did not come in one full, fifteen-yard piece, I was unable to do the rightmost panel with a single piece of fabric. I had to use two pieces.

I used a staple gun to hold the fabric in place, and if a staple didn't go in far enough, I tapped it with a hammer.