Difference between revisions of "Diamond Radiator Thinning Using an Excimer Laser"

| Line 9: | Line 9: | ||

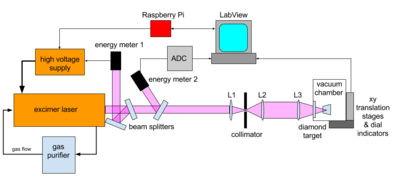

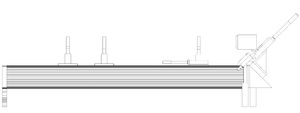

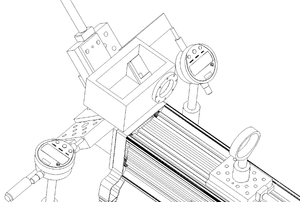

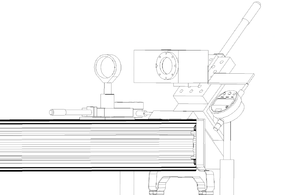

[[Image:expsetup.png|right|thumb|400px|Figure: Illustration of the experimental setup used to ablate diamond using a UV excimer laser at the University of Connecticut.]] | [[Image:expsetup.png|right|thumb|400px|Figure: Illustration of the experimental setup used to ablate diamond using a UV excimer laser at the University of Connecticut.]] | ||

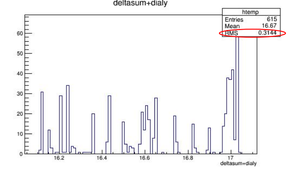

| − | A research group at Brookhaven National Laboratory ([https://zeus.phys.uconn.edu/halld/diamonds/BNLdev-1-2009/smedley-1-2009_2.pdf BNL]) published results using a focused high-power UV laser to mill diamond via a process known as ablation. Lasers with wavelengths above the band gap of diamond (213 nm) [?] can excite electrons between the diamonds carbon atoms from a bound state to an ionized state. The top 100 nm of the diamond surface at the focal spot is instantly vaporized, emitting a plume of carbon-based plasma normal to the surface of the diamond crystal. By scanning the diamond across the focal spot, a sequence of overlapping spots is built up that results in uniformly milling the sample surface. The short duration (10 ns) and short absorption length (50 nm) of the laser pulse ensure that the pulse energy is absorbed in the upper 100 nm of the diamond and does not result in deep energy deposition in the bulk of the crystal. Most importantly, this technique allows the diamond to be thinned deferentially, creating a central window of 20 microns thickness while retaining the full thickness around the edges for stiffness and support. This would never be possible with an abrasive technique. The laser ablation technique on diamond was developed extensively here at UConn by the author, using a Lambda Physik EMG 101 excimer laser operating at a wavelength of 193 nm as the light source. An XYZ computer controlled stage was constructed to sweep the diamond (under a vacuum of 600 mtorr) across the laser focus. The bulk diamond crystal before machining is typically of size 7.2 x 7.2 x 0. | + | A research group at Brookhaven National Laboratory ([https://zeus.phys.uconn.edu/halld/diamonds/BNLdev-1-2009/smedley-1-2009_2.pdf BNL]) published results using a focused high-power UV laser to mill diamond via a process known as ablation. Lasers with wavelengths above the band gap of diamond (213 nm) [?] can excite electrons between the diamonds carbon atoms from a bound state to an ionized state. The top 100 nm of the diamond surface at the focal spot is instantly vaporized, emitting a plume of carbon-based plasma normal to the surface of the diamond crystal. By scanning the diamond across the focal spot, a sequence of overlapping spots is built up that results in uniformly milling the sample surface. The short duration (10 ns) and short absorption length (50 nm) of the laser pulse ensure that the pulse energy is absorbed in the upper 100 nm of the diamond and does not result in deep energy deposition in the bulk of the crystal. Most importantly, this technique allows the diamond to be thinned deferentially, creating a central window of 20 microns thickness while retaining the full thickness around the edges for stiffness and support. This would never be possible with an abrasive technique. The laser ablation technique on diamond was developed extensively here at UConn by the author, using a Lambda Physik EMG 101 excimer laser operating at a wavelength of 193 nm as the light source. An XYZ computer controlled stage was constructed to sweep the diamond (under a vacuum of 600 mtorr) across the laser focus. The bulk diamond crystal before machining is typically of size 7.2 x 7.2 x 0.250mm^3 . A series of laser pulses was applied to a rectangular region in the center of the diamond, milling a thin window down to the required thickness and leaving untouched a zone around the perimeter which is called the frame. The components of the experimental setup shown in Figure 1 are discussed in detail in the sections below. |

| − | |||

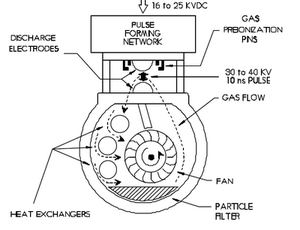

==Excimer Laser== | ==Excimer Laser== | ||

Revision as of 20:11, 13 December 2016

| Important Documents |

| UConn Laser Safety Manual |

| Excimer laser S.O.P. |

| Oxford GP 2000 User Manual |

Laser Thinning of Diamond

A research group at Brookhaven National Laboratory (BNL) published results using a focused high-power UV laser to mill diamond via a process known as ablation. Lasers with wavelengths above the band gap of diamond (213 nm) [?] can excite electrons between the diamonds carbon atoms from a bound state to an ionized state. The top 100 nm of the diamond surface at the focal spot is instantly vaporized, emitting a plume of carbon-based plasma normal to the surface of the diamond crystal. By scanning the diamond across the focal spot, a sequence of overlapping spots is built up that results in uniformly milling the sample surface. The short duration (10 ns) and short absorption length (50 nm) of the laser pulse ensure that the pulse energy is absorbed in the upper 100 nm of the diamond and does not result in deep energy deposition in the bulk of the crystal. Most importantly, this technique allows the diamond to be thinned deferentially, creating a central window of 20 microns thickness while retaining the full thickness around the edges for stiffness and support. This would never be possible with an abrasive technique. The laser ablation technique on diamond was developed extensively here at UConn by the author, using a Lambda Physik EMG 101 excimer laser operating at a wavelength of 193 nm as the light source. An XYZ computer controlled stage was constructed to sweep the diamond (under a vacuum of 600 mtorr) across the laser focus. The bulk diamond crystal before machining is typically of size 7.2 x 7.2 x 0.250mm^3 . A series of laser pulses was applied to a rectangular region in the center of the diamond, milling a thin window down to the required thickness and leaving untouched a zone around the perimeter which is called the frame. The components of the experimental setup shown in Figure 1 are discussed in detail in the sections below.

Excimer Laser

Specs on EMG 101 MSC excimer laser.

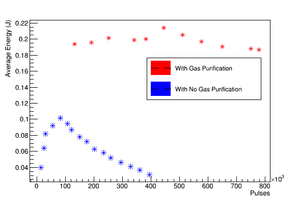

Gas Purification System

specs on GP2000

Laser Beamline

laser optics

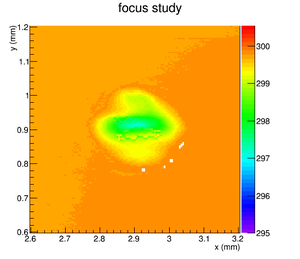

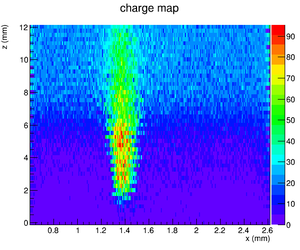

Focal Study

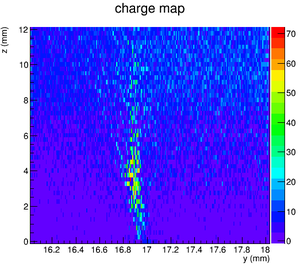

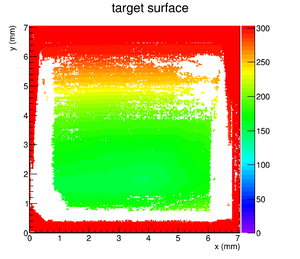

- Color maps of the two orthoganol scans of beam focal region, where the color represents the charge per pulse seen on the wire in arbitrary units.

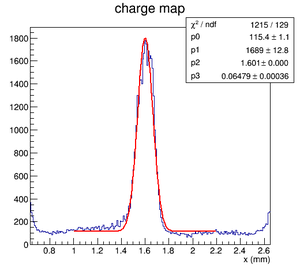

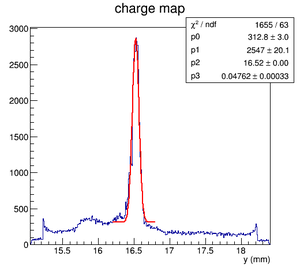

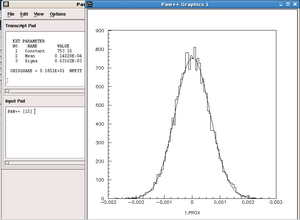

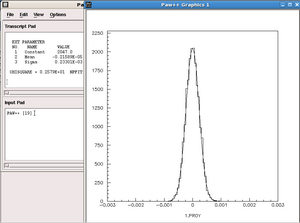

- Projections of the color maps shown in Figure 6 onto the transverse axis with Gaussian fits to central peak over a flat background.]]

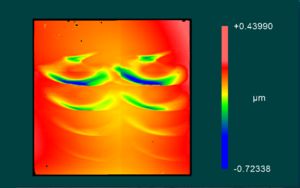

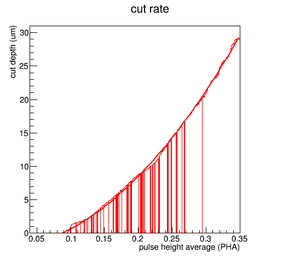

Ablation Rate

ablation rate

FORTRAN Simulations of Beam Spot

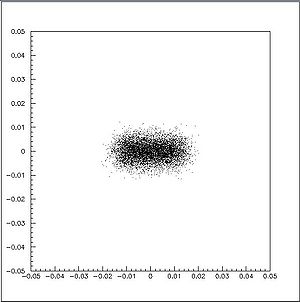

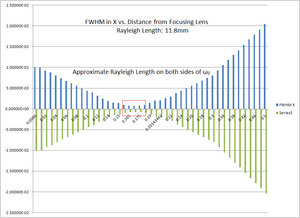

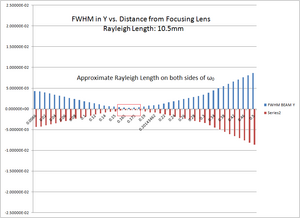

- A FORTRAN program has been written which simulates rays exiting the laser aperture and then propagating through a fused silica plano-convex lens. Using this program we can now observe the geometry of the beam as it passes through the focusing lens onto a target. We have seen that the beam leaving the laser aperture has a flat top distribution in the X plane and a Gaussian distribution in the Y. As the beam is focused both the X and Y projections achieve Gaussian distributions.

- Taking the X and Y projections of the focused beam and fitting them with a Gaussian distribution,we are able to attain and .

- Assuming a Gaussian distribution at the waist of the beam, we now find the FWHM (full width at half maximum) by the following relation,

- The smallest values of and were 1.49mm and 0.552mm respectively.

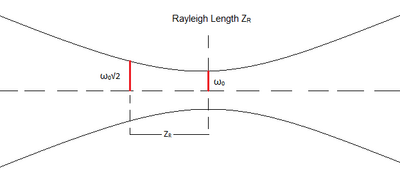

- The Rayleigh Length, is defined as the distance from the beam waist along the axis of propagation to the point where its cross section is doubled (). This value represents the "play" we will have when trying to focus the beam onto the diamond target for ablation. Taking as the beam waist, and using the as its value we are looking for the point where,

- Plotting as a function of distance away from the beam waist center, we find an average Rayleigh Length,

- and

- Knowing also allows us to calculate the theoretical fluence of the beam. Assuming maximum power of 220mJ over a 1.49mm x 0.552mm area yields Which is above the threshold value cited by Brookhaven National Laboratories who were conducting diamond ablation experiments with a 213nm Nd:YAG laser (213nm with the use of a 4 + 1 frequency mixing crystal). Our ArF excimer laser produces 193nm light that will be more readily absorbed by the surface of the diamond as diamond is opaque to wavelengths above the band gap. These calculations provide a level of confidence that we theoretically will be able to ablate diamond.

Ablation Chamber

Ablation Rate

XYZ Translation Stages

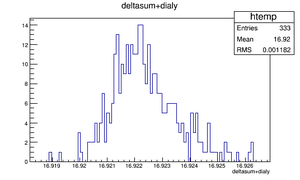

Sub-Micron Precision Using Dial Indicators

Ablation Software

- ablator.C: Core software used in creating ablation raster files.

- ablator.h: Header file for ablator.

- Map2D.cc: Package required to run ablator.

- Map2D.h: Header file for Map2D.

- ablate.py: Python module with custom methods for processing Zygo images for use in ablator.

- zygo2root.C: Software for converting hitched Zygo data files into root files.

- zfinder.cc: Package needed for zygo2root

- MetroProMap.cc: Package needed to run Zygo2root software.

- MetroProMap.h : Header file for MetroProMap.

- setenv.sh: sample of environment variables required to run above software.