Difference between revisions of "Epoxy Tests"

Jump to navigation

Jump to search

m |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | To test whether the fibers could be protected from the damage from ethanol, the ends of fibers were covered with Saint Gobain's BC-600 fiber cement. The instructions for use and more information on BC-600 can be found [http://www.detectors.saint-gobain.com/uploadedFiles/SGdetectors/Documents/Product_Data_Sheets/BC600-Data-Sheet.pdf here.] | ||

| + | |||

| + | Tips on epoxy use and other test procedures can be found [https://docs.google.com/a/uconn.edu/document/d/1yUTqVM172Ta29nQGRo3gLhZzoSG-CtZQL-JCNUg0j8k here.] | ||

| + | |||

| + | ==Data== | ||

| + | |||

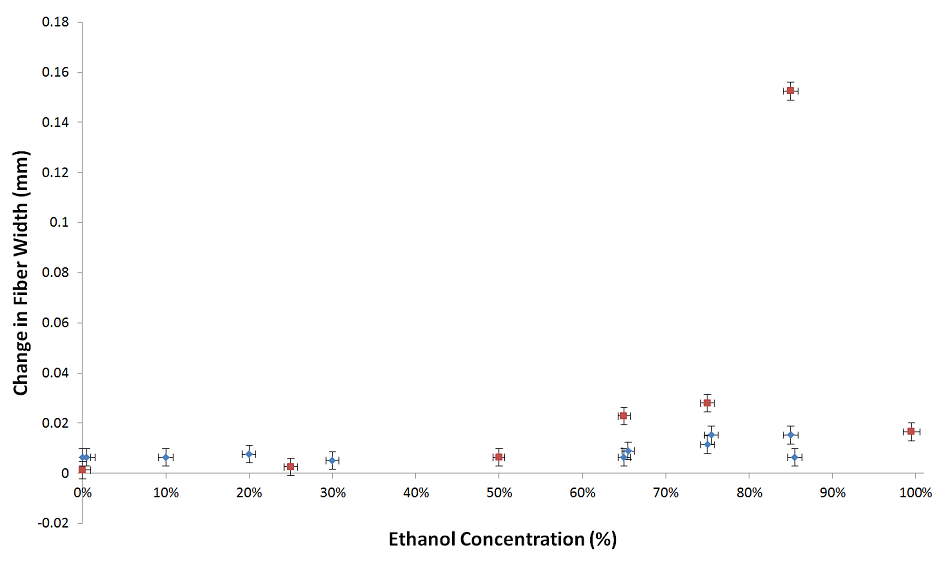

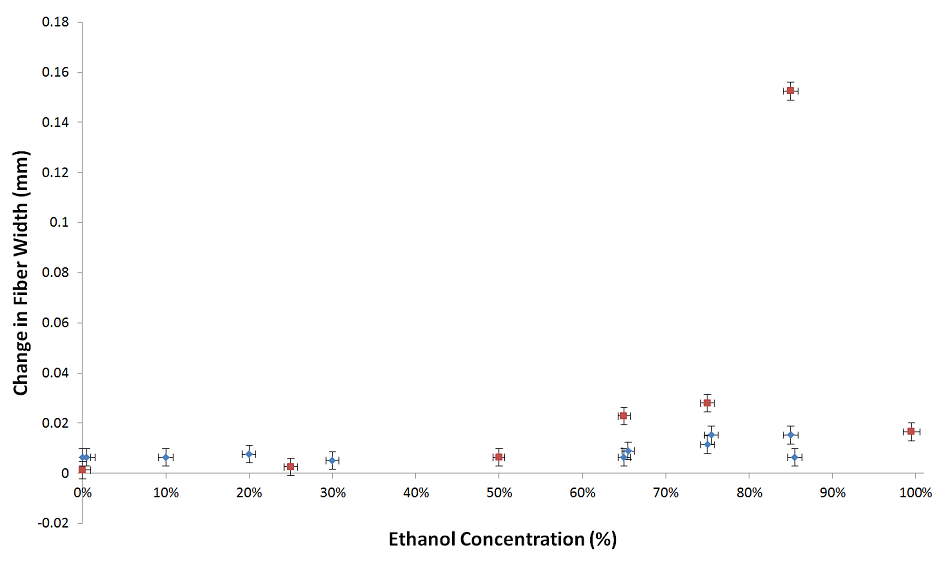

[[File:Epoxy_Test_1.png|frame|center|This is a graph of the results from Epoxy Test 1 and it's respective Alcohol Test. This test was run for 24 hours in room temperature conditions. The red data points are the fibers which were not epoxied. The blue data points are the fibers which were coated in BC-600. The epoxied fibers had a smaller change in fiber size, but also experienced their greatest change around the 75%-85% concentration. ]] | [[File:Epoxy_Test_1.png|frame|center|This is a graph of the results from Epoxy Test 1 and it's respective Alcohol Test. This test was run for 24 hours in room temperature conditions. The red data points are the fibers which were not epoxied. The blue data points are the fibers which were coated in BC-600. The epoxied fibers had a smaller change in fiber size, but also experienced their greatest change around the 75%-85% concentration. ]] | ||

Latest revision as of 18:31, 23 July 2013

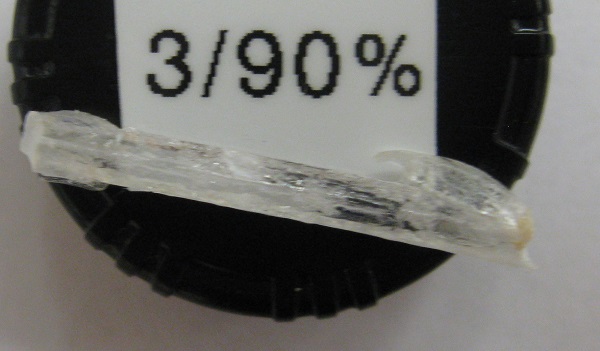

To test whether the fibers could be protected from the damage from ethanol, the ends of fibers were covered with Saint Gobain's BC-600 fiber cement. The instructions for use and more information on BC-600 can be found here.

Tips on epoxy use and other test procedures can be found here.

Data

This is a graph of the results from Epoxy Test 1 and it's respective Alcohol Test. This test was run for 24 hours in room temperature conditions. The red data points are the fibers which were not epoxied. The blue data points are the fibers which were coated in BC-600. The epoxied fibers had a smaller change in fiber size, but also experienced their greatest change around the 75%-85% concentration.

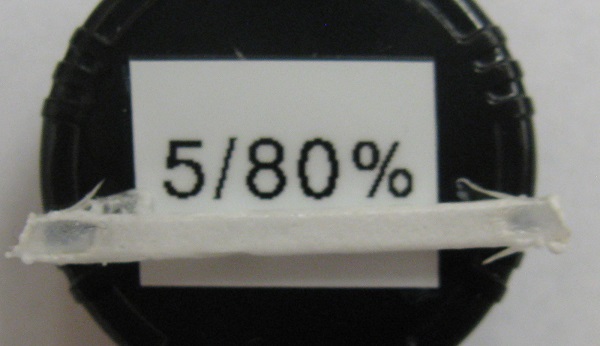

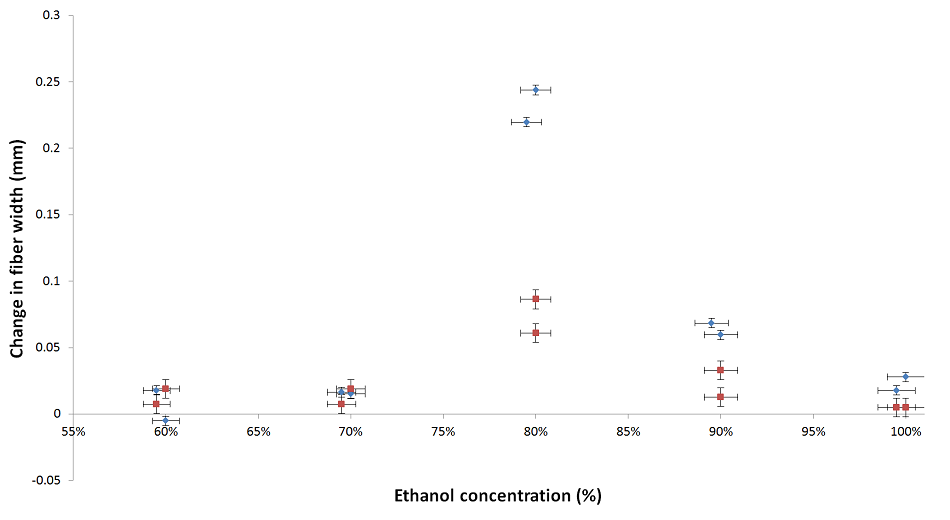

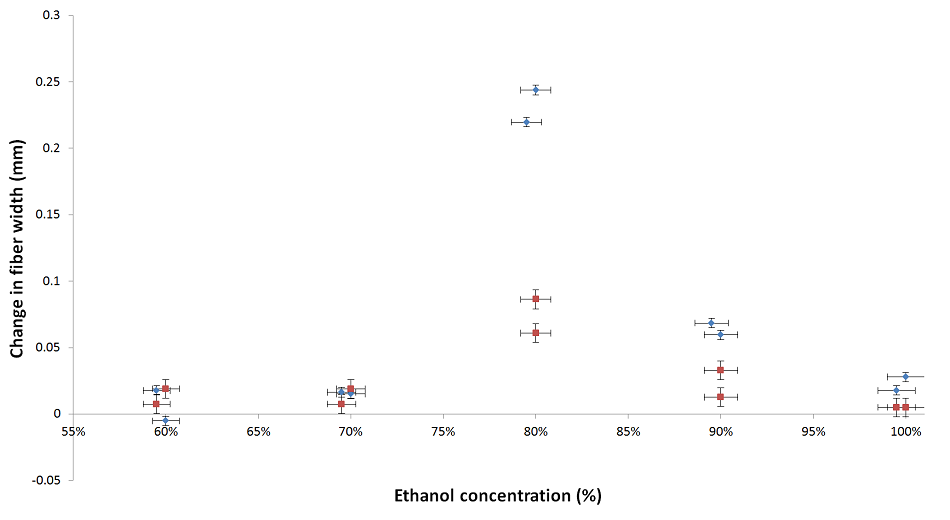

This is a plot of Epoxy Test 2, where the epoxied fibers rested for 5 days in room temperature water. Again, the epoxied fiber data is blue, and it is plotted against the non-epoxied red data. Here, the epoxied fibers actually had a greater change in fiber width than the non-epoxied fibers after the 70% mark.

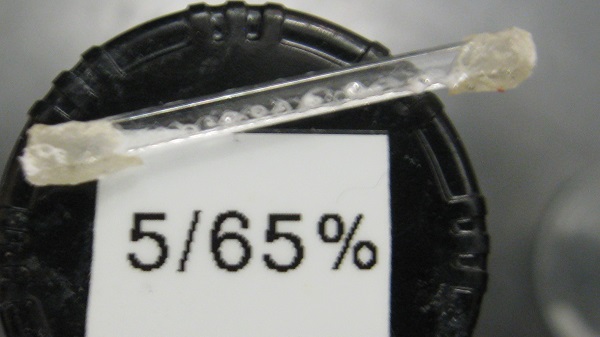

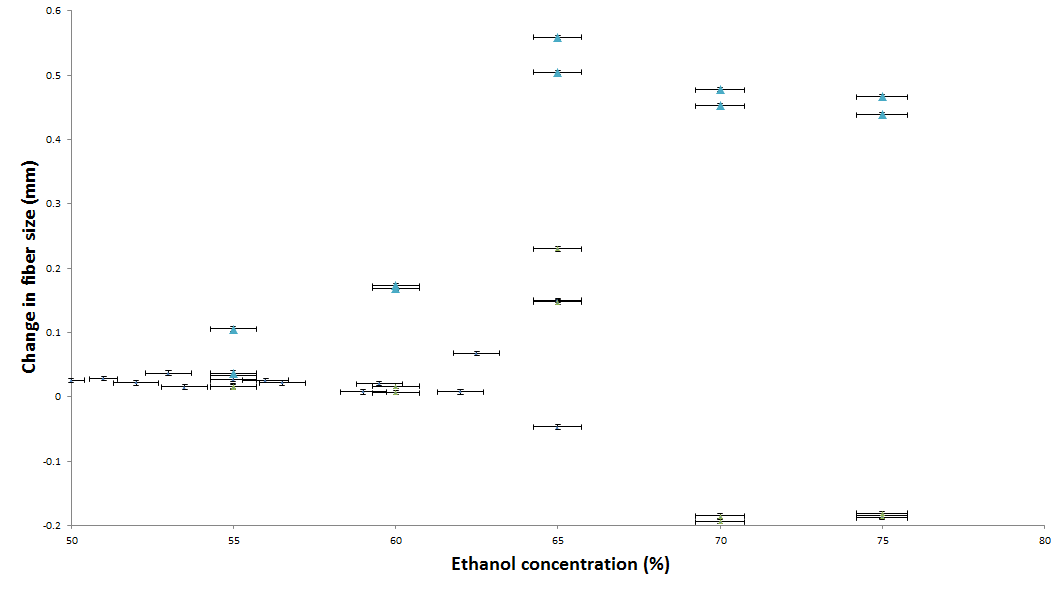

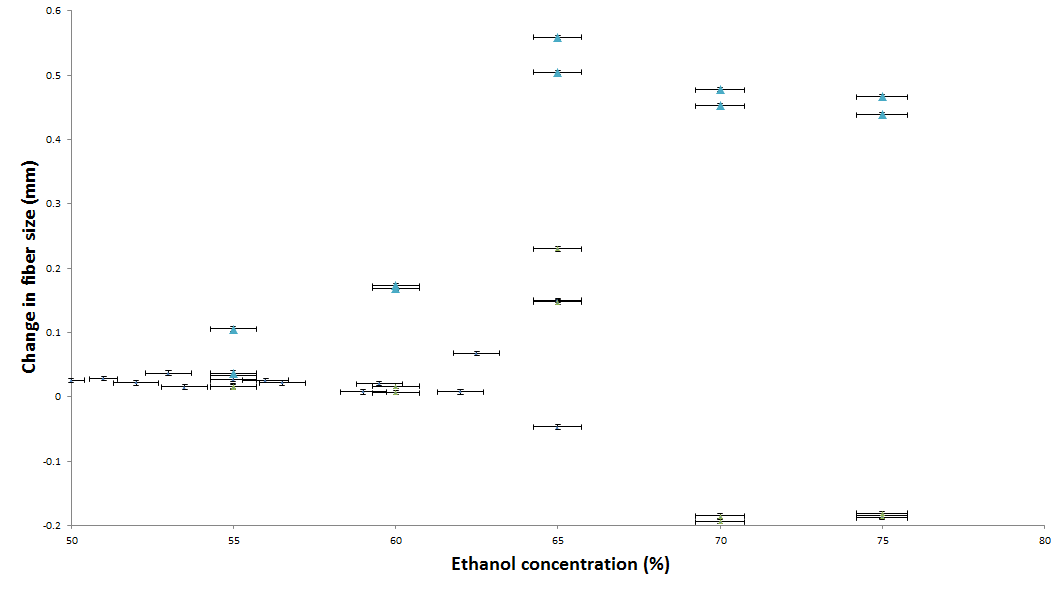

In Epoxy Test 3, the epoxied fibers were placed in heated ethanol. They were placed in concentrations of 55%, 60%, 65%, 70%, and 75% ethanol because these were the concentrations where the most severe damage occurred for the non-epoxied heated ethanol tests. The epoxied fibers of test 3 are represented in the plot above with large blue triangles, and the rest of the data, despite color, is from the previous heated alcohol tests. Here, as seen in Epoxy Test 2, the epoxied fibers had a greater change in fiber width than the non-epoxied fibers.