Difference between revisions of "Digital control board debugging notes"

Senderovich (talk | contribs) m |

Senderovich (talk | contribs) |

||

| (2 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

This page contains a list of all currently known problems with the digital control board. | This page contains a list of all currently known problems with the digital control board. | ||

| − | = | + | == Resistor on DAC temperature measurement diode too high == |

| + | === Description === | ||

| + | When the readout is programmed using the DAC manual's coefficients and offset, the temperature value ends up tens of degrees off. | ||

| + | |||

| + | === Cause/Solution === | ||

| + | The board was designed with R1=270kΩ to sink the current from the DAC's internal temperature-measuring diode to ground. The manual specifies the expected diode drop at 25degC will be 0.65V at a current of 100uA. Given the sensitivity of this device (with a coefficient of 2.2mV/degC) it is seems best to match their measurement conditions and adjust the resistor so that 0.65V drop from the biasing 5V results in 100uA through the resistor. So, ''R1 should be set to 43.5kΩ''. | ||

| + | |||

| + | Three parallel resistors have been soldered into place on the prototype board providing a nominal R1 of 43.6kΩ. The readout values are now reasonable. | ||

| + | |||

== No Power on +1.2V Power Island == | == No Power on +1.2V Power Island == | ||

| Line 68: | Line 76: | ||

| − | == | + | == Ethernet jack pinout mismatch == |

| − | |||

| − | |||

| − | |||

| + | The wrong Ethernet jack was attached to the PCB, leading to a pinout mismatch. The part ordered was the Pulse J001'''1'''D21. The correct part is J001'''2'''D21. The correct part was ordered and soldered onto the prototype boards, but this change must be made in the Altium parts list. | ||

= Suggested/Preferred Changes = | = Suggested/Preferred Changes = | ||

* <code>R12</code>, the pull-up resistor for the reset pins (header 2) is unnecessary, as the FPGA pin can be programmed to pull up. | * <code>R12</code>, the pull-up resistor for the reset pins (header 2) is unnecessary, as the FPGA pin can be programmed to pull up. | ||

Latest revision as of 15:38, 30 September 2010

This page contains a list of all currently known problems with the digital control board.

Resistor on DAC temperature measurement diode too high

Description

When the readout is programmed using the DAC manual's coefficients and offset, the temperature value ends up tens of degrees off.

Cause/Solution

The board was designed with R1=270kΩ to sink the current from the DAC's internal temperature-measuring diode to ground. The manual specifies the expected diode drop at 25degC will be 0.65V at a current of 100uA. Given the sensitivity of this device (with a coefficient of 2.2mV/degC) it is seems best to match their measurement conditions and adjust the resistor so that 0.65V drop from the biasing 5V results in 100uA through the resistor. So, R1 should be set to 43.5kΩ.

Three parallel resistors have been soldered into place on the prototype board providing a nominal R1 of 43.6kΩ. The readout values are now reasonable.

No Power on +1.2V Power Island

Description

The +1.2V island was found to be at 0.0V rather than +1.2V.

Cause

The +5V input (pin 2) on the +1.2V voltage regulator, VR3 (Analog Devices ADP1715), was not connected.

Solution

A dab of solder was used to short pins 1 and 2 on VR3. Pin 1 is an active high chip enable pin, which is permanently tied to +5V.

Other Details and Current Status

This problem was due to an unconnected pin in the original schematics. The schematics have not yet been updated to reflect the solution.

- June 22, 2009: One board has been modified to correct this problem.

SPI Bus Miswired

Description

The SPI bus to the temperature sensor and the ADC is not wired correctly.

Cause

FPGA pin 5 (labelled SPI) is connected to DIN on the ADC, and DOUT of the temperature sensor. FPGA pin 97 (labelled AD7928/DOUT) is connected to DOUT on the ADC. SPI designates that all slave device DOUT traces be connected together. Chip select and HiZ logic are used to prevent devices from fighting over the signal line.

Solution

Pin 5 on the temperature sensor should be connected to pin 18 on the ADC and pin 97 on the FPGA. This can be accomplished by cutting the existing DOUT trace near the temperature sensor and soldering a wire to DOUT on the ADC. In this configuration, pin 5 on the FPGA will become the SPI MOSI (master out, slave in) line, and pin 97 on the FPGA will become the SPI MISO (master in, slave out) line. DIN on the temperature sensor is left tied to ground, since it is not needed.

Other Details and Current Status

This problem was due to errors int he original schematics. The schematics have not yet been updated to reflect the solution.

This modification has been implemented.

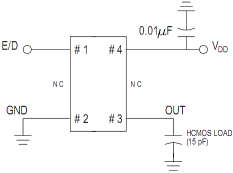

Incorrect Oscillator

Description

The oscillator used was a standard crystal oscillator, however the FPGA requires an oscillator with a CMOS square wave input.

Solution

The crystal oscillator was replaced with a FOX FXO-HC53 HCMOS oscillator running at 20 Mhz. The output from the oscillator was connected to pin 27 on the FPGA. The load of having both the oscillator and the Ethernet controller connected to the output of the oscillator was to large. The clock input for the Ethernet controller Pin 28 was connected to pin 37 of the FPGA.

Schematic:

Other Details and Current Status

The schematics have not yet been updated to reflect the solution.

This modification has been implemented.

Wrong polarity of Zener Diode on -5V

Description

Zener diode D2 is reversed in the layout. It is correct in the schematics.

Solution

The diode was rotated on all the prototyping boards. This indication has not yet been entered into the layout.

Other Details and Current Status

This problem may be related to the overload on the -5V circuitry for of the DAC.

Mismatched JTAG programming header

Description

The connector of the "Xilinx Platform USB II" kit seems to be a reduced size compared to the standard 0.1" spaced pin header with which the board is equipped.

Solution

For the testing stage, the flying lead connector is sufficient to bypass this problem. The layout must be corrected to the matching header (type?). Change entered already?

Ethernet jack pinout mismatch

The wrong Ethernet jack was attached to the PCB, leading to a pinout mismatch. The part ordered was the Pulse J0011D21. The correct part is J0012D21. The correct part was ordered and soldered onto the prototype boards, but this change must be made in the Altium parts list.

Suggested/Preferred Changes

R12, the pull-up resistor for the reset pins (header 2) is unnecessary, as the FPGA pin can be programmed to pull up.