Difference between revisions of "ParSA Results"

| Line 2: | Line 2: | ||

=== Interferograms === | === Interferograms === | ||

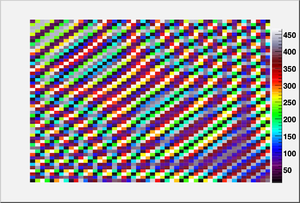

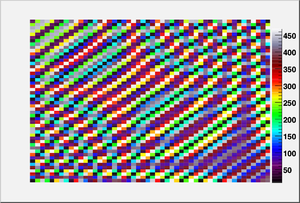

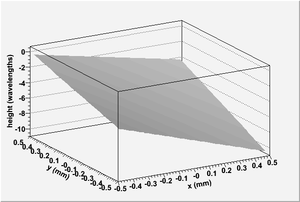

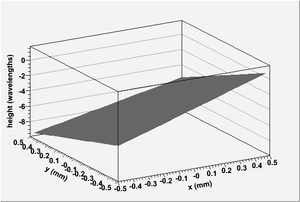

| + | The set of images in Fig. 1 and Fig. 2 depict the test interferogram analyzed using ParSA and the best interferogram solution found by ParSA. When compared visually, the two interferograms are nearly indistinguishable. This comparison shows that the solution found by the ParSA algorithm is a good one. | ||

| + | |||

{|align=center | {|align=center | ||

|[[Image:testprob-5-2008.png|thumb|Figure 1: The test interferogram created from three random surfaces.]] | |[[Image:testprob-5-2008.png|thumb|Figure 1: The test interferogram created from three random surfaces.]] | ||

|[[Image:bestsol-5-2008.png|thumb|Figure 2: The best solution found amongst several simulated annealing runs.]] | |[[Image:bestsol-5-2008.png|thumb|Figure 2: The best solution found amongst several simulated annealing runs.]] | ||

|} | |} | ||

| − | |||

=== Surfaces === | === Surfaces === | ||

Revision as of 07:59, 2 June 2008

Solutions

Interferograms

The set of images in Fig. 1 and Fig. 2 depict the test interferogram analyzed using ParSA and the best interferogram solution found by ParSA. When compared visually, the two interferograms are nearly indistinguishable. This comparison shows that the solution found by the ParSA algorithm is a good one.

Surfaces

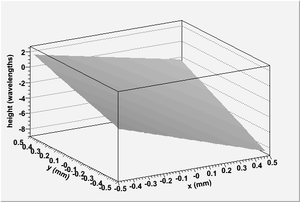

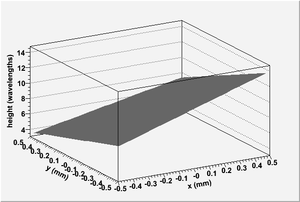

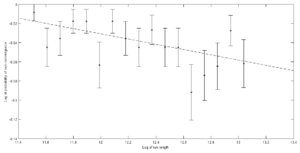

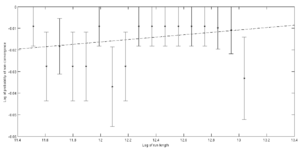

Fig. 3 and Fig. 5 show the front and back surfaces of the diamond wafer used to create the test interferogram depicted in Fig. 1. Fig. 4 and Fig. 6 show the solutions found by the ParSA algorithm which generated the interferogram shown in Fig. 2. The incident light used to create each of the interferograms is incident in the z-direction. The test diamond surfaces are the same shape and are apparently planar, with the exception that they have a small contribution from a second order Legendre polynomial . This slight curvature can be seen in the complex dark and light band structure depicted in Fig. 1. If the surfaces were actually planar as they appear, the resulting interferogram would not have these rich features and would simply be a series of straight, equally-spaced, light and dark bands.

The solutions found by simulated annealing feature two ambiguities that are a result of the nature of light. The first ambiguity results from the fact that a mirror transformation of the surfaces about a vertical plane do not change the interferogram. The second ambiguity is a result of the periodic nature of light and can be seen in differences present in the distances between surfaces between the test and solution surfaces.